Scientists from Perm National Research Polytechnic University (PNRPU) have developed a new hardware and software complex that increases diagnostic reliability by 80% compared to existing analogues.

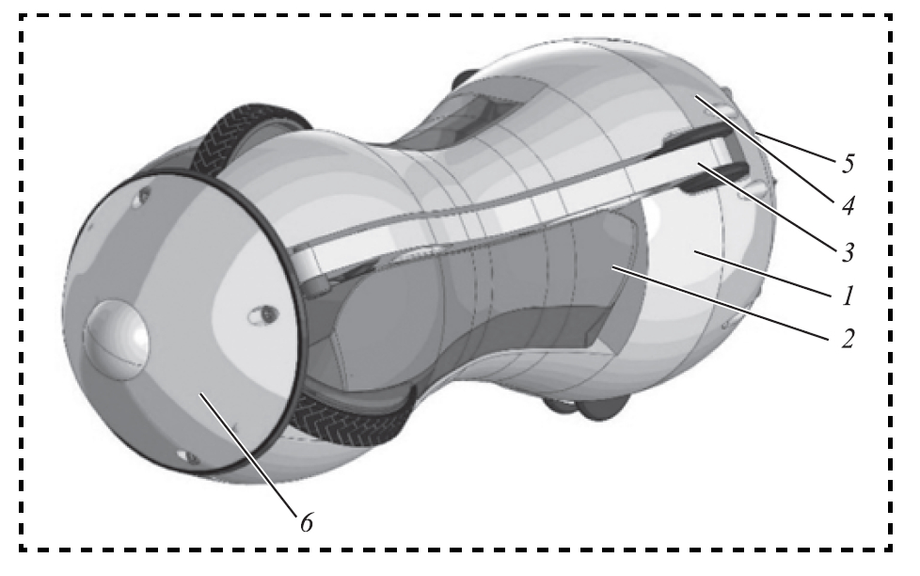

The development is based on the use of two microcontrollers — Raspberry Pi 4 and Arduino Nano, which share tasks. The first is responsible for processing the video stream from the camera, collecting data from sensors, and communicating with the operator, while the second specializes in controlling the motor system. This separation of functions reduces the load on each component and minimizes the likelihood of failures. An additional advantage was the use of a more powerful 43 Amp driver, which allows the use of high-performance motors without the risk of overload.

Systems with one or two controllers for controlling in-pipe robots already exist, but they have their drawbacks. Firstly, the parts for them are usually made to order, which increases the cost of equipment and complicates the manufacturing process. Secondly, it often happens that one of the components fails — in this case, the entire system is turned off after it. In addition, they usually use rather weak motor control drivers — with a maximum power of 5 Amps, which is not enough for all motors. As a result, the uptime of the robot is reduced, it may not have time to inspect all sections of the pipeline and identify all defects.

During testing, the system demonstrated impressive results. The average uptime was 10.87 hours, which is almost twice as high as that of analogues using only one controller. In addition, the failure rate decreased by 80.5%.

The control system was tested on a robot prototype in laboratory conditions. It successfully overcame sections of pipelines with complex geometry: two consecutive 90° bends and a transition to a straight section. As experiments have shown, our system experiences 80.5% fewer failures than a similar complex that has only a Raspberry Pi connected to drivers — this configuration is most often used in robotic devices. At maximum load conditions, the average uptime of our system was 10.87 hours, while that of the existing one was only 6.02 hours.

Another advantage is the availability of components. Unlike many specialized solutions, parts for this system can be purchased freely, which simplifies its implementation and maintenance. In addition, according to scientists, domestic analogues — Repka Pi and Smar Uno — can be used instead of foreign controllers.

The technology has already attracted the attention of major industrial companies, including Gazpromneft-Lubricants, Bashkir Distribution Heating Networks and T Plus.

Read more materials on the topic:

Personal robot trainer for runners created by DSTU engineers

Technology is taking revenge: delivery robot dropped a rider near a business center in Moscow

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation