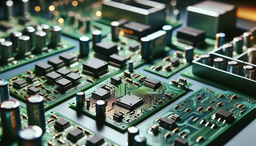

The tool production facility of PJSC "Kirov Plant \"Mayak\"" has completed the development of specialized tools for the production of new products. According to Sergey Dudash, Head of the Tool Shop, the company has prepared molds, dies, measuring and cutting tools necessary for the manufacture of highly complex parts.

Molds and dies, measuring and cutting tools, specialized tools that will be used for the manufacture of highly complex parts have been prepared.

According to the concern's press service, the successful completion of tasks within the established timeframe was made possible thanks to the practical skills and professionalism of the plant's tool shop workers. The competent selection of materials and processing methods played an important role. The use of modern technologies, including CAD/CAM systems for design, multi-axis CNC machines, and electrical discharge equipment, was also significant. The introduction of a five-axis milling machine and a turning processing center has improved processing accuracy and quality. The use of alloy steels has increased the strength and durability of the tools.

The new production facilities meet the requirements of the Russian machine tool industry and open up opportunities for the production of high-tech products.

Read more on the topic:

The road to automation: KAMAZ introduces robotic systems for the production of key parts

Chepetsky Mechanical Plant receives several awards at the All-Russian competition