Scientists from South Ural State University have successfully completed the development of innovative computational algorithms. These algorithms are designed to replace Japanese hydraulic actuators used by aerospace companies in vibration test benches. In addition, they can be useful for designing earthquake-resistant buildings.

SUSU scientists were asked to make a hydraulic drive, which is the basis of the test bench. The scientists came to the conclusion that they can achieve much better characteristics, since they have successfully developed new unique computer programs that serve to calculate the dynamic mode of the electric drive and calculate the magnetic system using a modernized finite element method.

The university explained that with the help of the developed programs, it is possible to solve a complex engineering problem: to create a drive that will effectively replace imported analogues, but at the same time work quickly and consume a minimum of energy. To achieve this goal, it is necessary to find the optimal ratio between the shape of the magnetic system and the position of the moving armature.

Therefore, in the course of synthesis and analysis, scientists solved another scientific problem: the well-known finite element method was modernized, which shows good results in calculating magnetic fields.

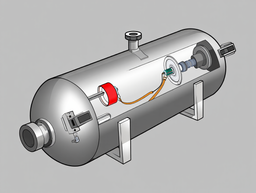

The test bench using the new Russian hydraulic drive allows testing spacecraft and building structures in conditions that are as close as possible to real ones. This makes it possible to eliminate all shortcomings and errors in the design before use.

Earlier, the Yu.A. Gagarin Saratov State Technical University developed unique equipment designed for the construction of bored piles. The installation is distinguished by its small dimensions and weight, in contrast to similar models.

Read more materials on the topic:

TPU Developed Fluoroplastic Coatings to Protect Chemical Reactors from Corrosion