Tomsk Polytechnic University has developed an innovative approach to introducing graphene into materials for bone implants. This was reported in the press service of the university.

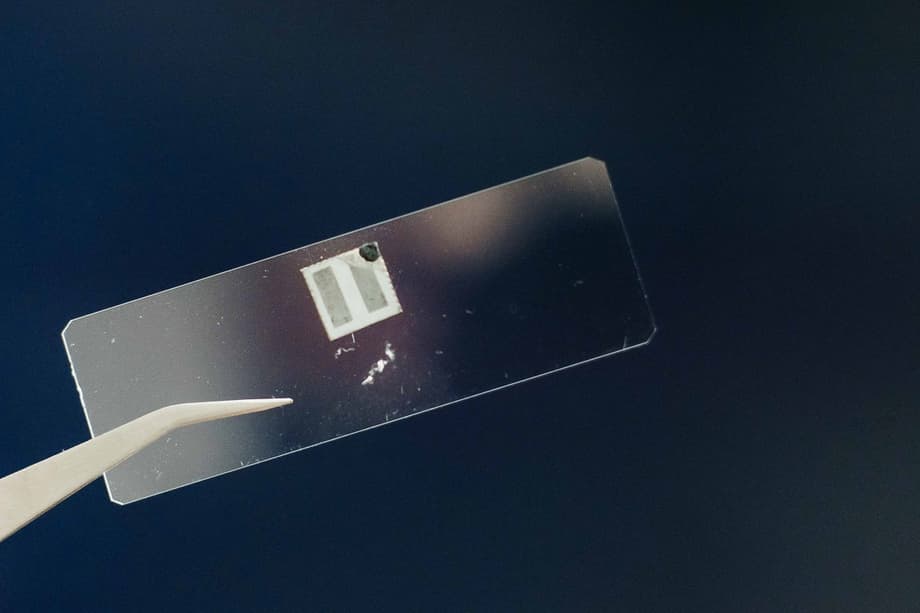

The new technology allows "drawing" biocompatible electrical circuits on the surface of non-conductive bone implants. Scientists used a laser processing method to integrate electrically conductive graphene into a titanium plate with a calcium phosphate coating, which is widely used in orthopedics and dentistry.

The resulting composite demonstrated excellent strength, withstanding a sand abrasion test for two hours and a load of 100 thousand bending cycles without compromising electrical characteristics. The electrochemical stability of the material was maintained after a million pulsed current cycles.

The creation of a new material could become the basis for the development of "smart" implants. In the future, a sensor can be integrated into the implant to monitor the load and signal deformation or destruction.

The integration of electrically conductive materials may allow "physiotherapy" using electrical stimulation or heating, which will improve blood circulation and accelerate cell growth. In the near future, scientists plan to investigate whether the new composite can promote cell growth for accelerated healing of injuries.

Within a week, human osteosarcoma cells were cultured on the surface of the composite under laboratory conditions. The biomaterial proved to be non-toxic to cell cultures, which is the first step in a chain of studies necessary to prove the safety of the new composite for humans.

Earlierwww1.ru reported that the Moscow Production Association "Metallist"developed the bionic knee module "Kometa".

Read materials on the topic:

Roscosmos' "daughter" increased the production of robotic knee prostheses by 30%

Masking pads for leg prostheses have been developed in St. Petersburg

Precise grip: PNIPU scientists have made their bionic hand prostheses more accurate