Rostec has found a way to increase the strength of aircraft parts by 20%. UAC enterprises have begun producing parts with a bionic design, which borrows solutions suggested by nature for the power elements of the aircraft's airframe.

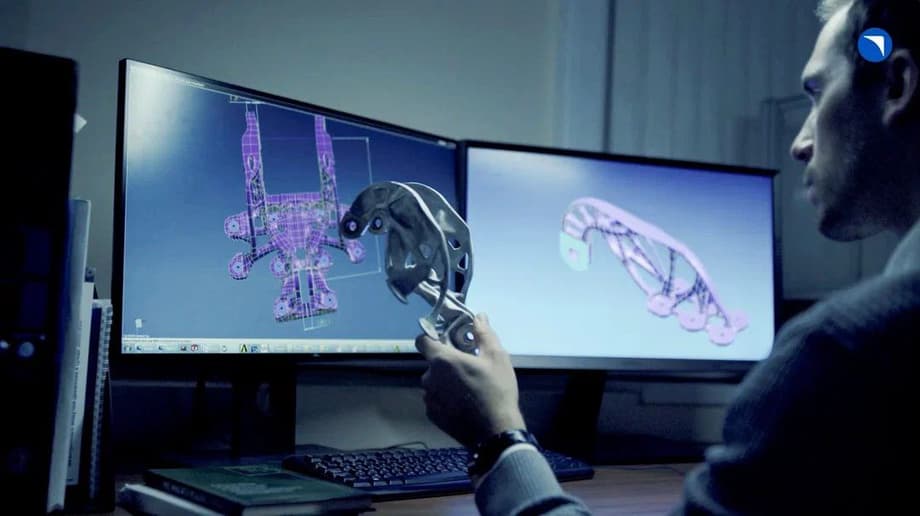

This approach is used in the design of components manufactured using additive technologies. These parts differ from traditional ones: they have branched and mesh structures resembling plants or mammalian bones.

One example of this approach is the bracket for the Su-57 aircraft, made by the Sukhoi Design Bureau. This is an aluminum part that looks more like a bone of a prehistoric animal than a regular part of a fifth-generation fighter. This bracket turned out to be 10% lighter than similar products made using traditional technologies, while its specific strength increased by 20%.

Bionic design, combined with additive technologies, saves expensive raw materials, including complex alloys and rare metals. It also leads to a reduction in material consumption by 10-30% in some cases, which has a positive effect on the cost of production.

Read more on the topic:

Unique technology of hollow fan blade for PD-14 developed in Russia

Rostec started developing a replacement for fighter pilots with artificial intelligence

Now on home

Netizens believe that UAVs are better replaced by thousands of small satellites at an altitude of 200 km

Likhachev: We are ready to offer Serbia the entire range of our projects

Fraudsters have learned to imitate the interface of a bank and payment system

The truck can operate as part of road trains weighing up to 100 tons

Work on the high-speed maglev body has already begun

The first stages of the program are planned to be completed by 2032

Recovery teams are working at the scene

The fifth prototype was accelerated to 190 km/h at an altitude of 300 meters

Over the past two years, the growth rate in this segment has been at 15%

Experts got acquainted with the key objects of the experimental base and advanced methods of certification flights

In annual reports, parliamentarians willingly share statistics from their channels

The university is also working on creating robotic manipulators and robotic welders