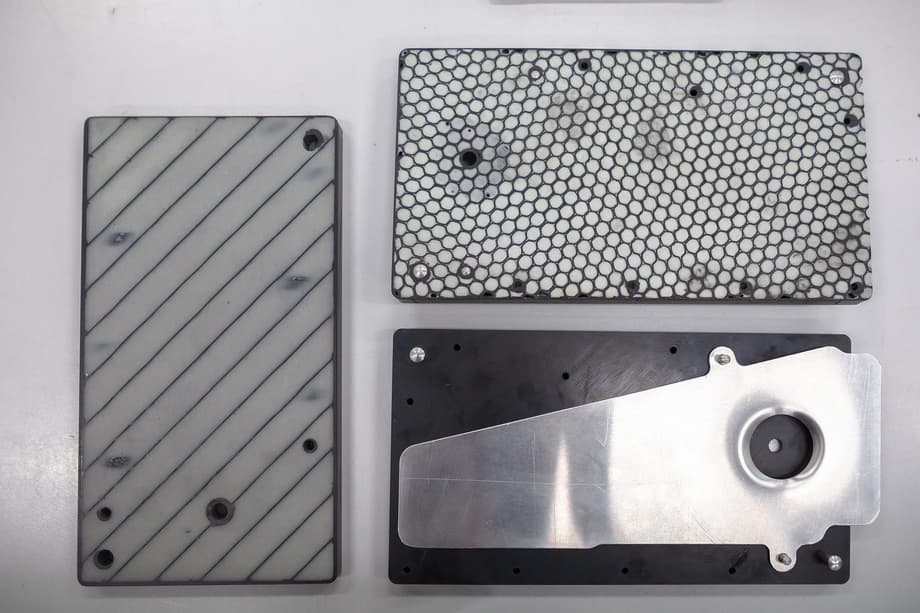

ISTU employees have developed a new method of 3D printing for creating polymer tooling for stamping sheet metal aircraft parts. A plastic mold made in this way can form aluminum blanks with a thickness of 1.5 mm. At the same time, the mold is printed four times faster than its counterparts: in 12 hours instead of 48 hours.

The innovative technical solution is the result of the work of ISTU scientists within the framework of the Priority 2030 program.

For casting, we use thermosets - plastics that can harden like concrete. Experimenting with casting technology and special fillers for tooling, we tested glass and graphite powder, and aluminum powder. The task was to find the optimal composition, thanks to which the mold would deform less under heavy loads. The result showed that the printed plastic mold perfectly withstands the working loads of the press. According to the technology we proposed, the tooling is produced in a shorter time and has a lower cost.

According to Shemetov, specialists from the Irkutsk Aviation Plant - a branch of PJSC Yakovlev, became interested in the new tooling manufacturing technology. The factory workers still have to resolve issues related to the tooling's resources and its strength.

Read materials on the topic:

Will create aircraft parts weighing up to 20 tons - how the largest gas holder in Russia works