Ruselectronics demonstrated the production process of airships and aerostats, carried out at the facilities of DKBA, which is part of the corporation.

The production is based on the use of specialized fabric-film materials, which guarantee high strength and reliable gas-holding properties of the final products.

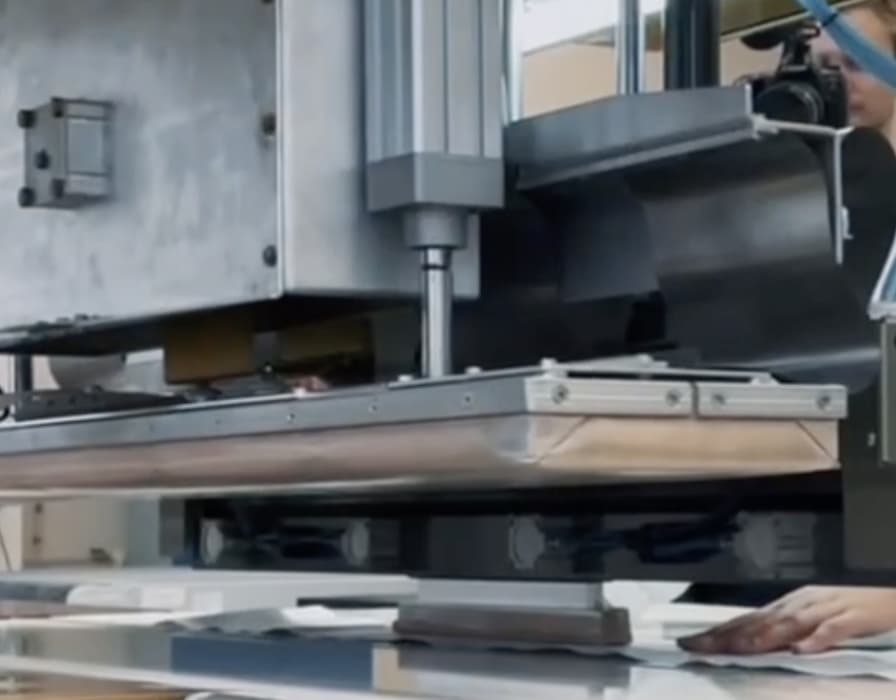

The cutting process is fully automated: electronic drawings direct the operation of the cutting complex, which precisely marks and cuts the fabric using a laser knife.

Simple parts are welded with high-frequency currents, ensuring reliable connection. More complex elements with radius angles are glued manually using thermocontact rollers. In both cases, the resulting seam is stronger than the material itself, which emphasizes the high quality and durability of the products.

Read more on the topic:

Return of the Zeppelin Era: Ruselectronics and Bauman University to Develop Aerostat Technology