The Special Design Bureau -3 (part of the military-industrial holding company "Kingisepp Machine-Building Plant") has created a method for casting mold tooling. The technology was successfully used in the production of gas turbine engine blades for the order of LLC "SEMAKS METALL". This was reported by the press service of the enterprise.

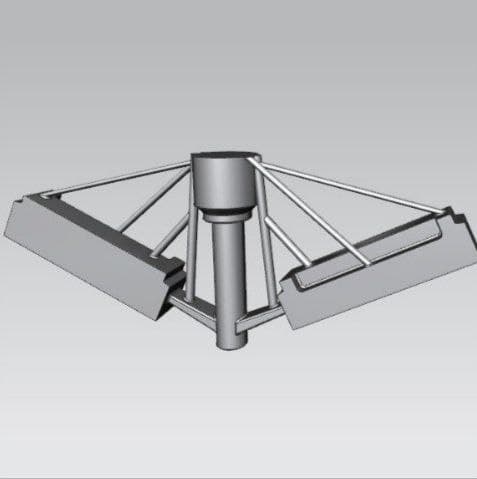

The production task was to design casting technology. For this purpose, they were created from a nickel-based alloy ZhS6U. It cannot be remelted in an induction furnace during open melting.

A casting technology was developed for the vacuum induction remelting method in a specialized unit in the Zimitsy casting shop. The castings were made without a single defect and shipped to the customer.

Turbine blades are used for the operation of gas turbine engines. The compressor compresses the air, it is fed into the combustion chamber of the gas turbine unit, mixed with natural gas and expands. Then the air enters the blades and creates pressure on the blades. This forces the shaft connected to the generator to move.

Earlier www1.ru reported that a new complex for assembling high-power gas turbines GTE-110M will be built in Russia.

Read materials on the topic:

Without Siemens and General Electric: Russia has freed itself from the import of large gas turbines

ODK is developing new engines for Russian aircraft, air taxis and drones

Rostec showed how 3D printing of aircraft engine parts works

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation