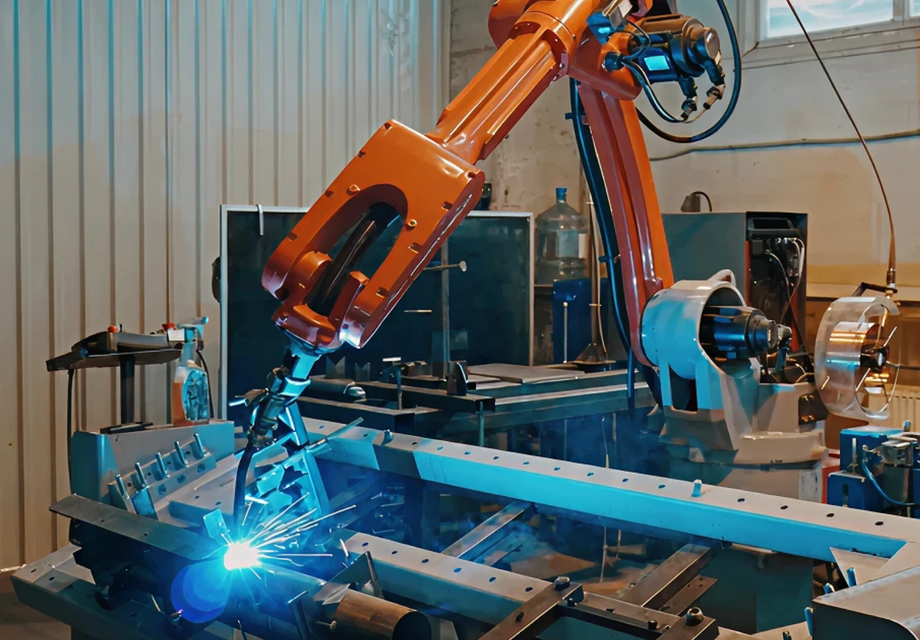

Leber, a manufacturer of children's playgrounds and sports grounds from Mytishchi, has implemented a robotic welding complex, which has made it possible to increase production efficiency fourfold, according to the "Made in Russia" portal.

Thanks to automation, it was possible to significantly increase the speed of production and improve its quality due to stronger connections.

The company noted that robotization freed welders from routine operations. Now, specialists are focused on complex tasks that require an individual approach.

The company uses a welding robot and seven conductors, which allows producing up to seven products simultaneously. This year, Leber products were supplied not only to Russia, but also abroad – to Qatar and Brazil.

Read also materials on the topic:

- Welder's salary 500 thousand: the Ministry of Construction revealed the reasons for record incomes in the construction industry

- «ZiO-Podolsk» introduced a welding robot for the production of NPP supports: labor costs reduced by 4 times

- Rostec presented a unique "smart" welding complex with automatic seam search