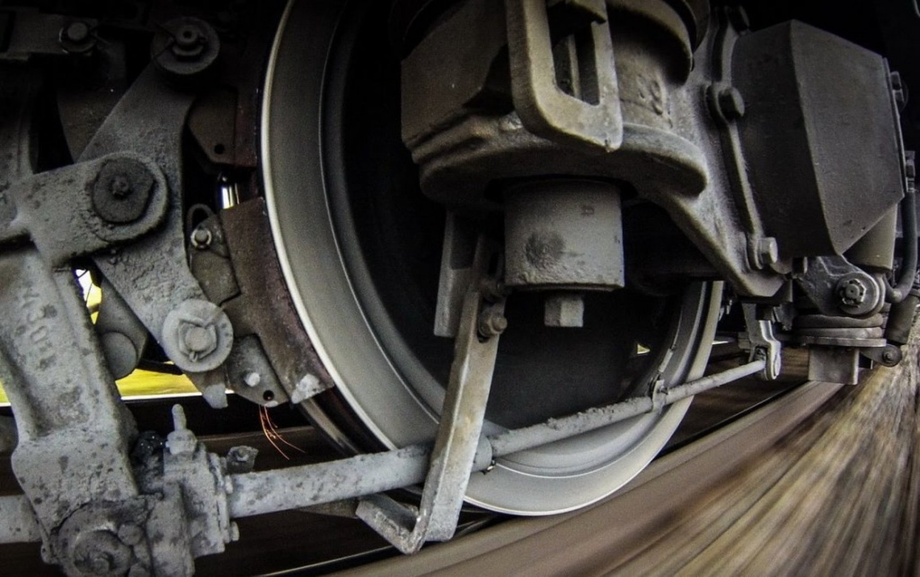

Young researchers from the Institute of Strength Physics and Materials Science SB RAS have created an advanced composite material for brake pads designed for new generation high-speed trains. This material demonstrates a sevenfold superiority in wear resistance compared to existing global counterparts.

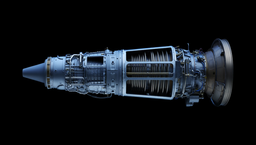

We have developed an innovative metal-ceramic composite material for brake pads for high-speed rail transport. A key feature of the development is the use of modern approaches to managing structure-dependent characteristics and structural design of composites simultaneously at various levels of the scale hierarchy.

Tomsk scientists abandoned the traditional approach to improving brake pads for high-speed trains, where ceramic particles are added to a copper matrix composite. The problem is the weak connection between them, which leads to wear and instability during friction.

In our work, we applied a "composite in composite" approach, which previously proved successful in the example of heat-shielding materials: we introduced pre-sintered metal-ceramic composite inclusions into the metal matrix. Thus, we achieved a high bond strength between the metal matrix and the ceramic reinforcing functional inclusions, prevented their tearing out and crumbling during friction, and achieved an increase in the stability of characteristics and reliability of product operation.

This approach made it possible to achieve a significant increase in the bond strength of metal and ceramics. The shear strength relative to the global standard composite for brake pads for high-speed transport increased by 30%, and the wear resistance increased sevenfold.

Read more on the topic:

The use of vibration diagnostics system is planned to be expanded to new industries in Russia

New development by Russian physicists will improve the safety of thermonuclear reactors