The Research and Technological Institute (NITI) "Progress" (part of Rostec) has developed a new video surveillance system that allows real-time monitoring of the electron beam welding process. This was reported by the press service of the state corporation.

The development surpasses existing domestic and foreign analogues. It will significantly improve the accuracy of welding operations and ensure prompt quality control of the weld.

The system is based on a magnetic optics unit that creates a high-quality image with a refresh rate of 200 frames per second. An electron beam scans the surface of the weld, and a secondary electron sensor converts the signal into a video image.

The video surveillance system is capable of recording operations. The data can be stored both on a local server and in cloud storage. Information is sorted by date, operator, and specific product, and can also be exported in various video formats, such as MP4, AVI, and MOV.

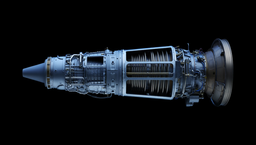

In essence, this is a modern method of non-destructive testing, similar to radiography. The complex can be in demand in various industries where electron beam welding is used. These include, for example, aircraft and engine construction, the nuclear industry, shipbuilding, and the space industry.

In the future, it is planned to improve the technology, which will allow tracking the joint online using the received video image. This will ensure automatic correction of the welding beam trajectory, which will improve the efficiency and quality of welding operations.

Earlier www1.ru reported that UEC for the first time showed the welding of aircraft engine parts using friction technology.

Read materials on the topic:

Scientists at NSTU have developed magnetic pulse welding for joining aluminum and steel

Developed Russian high-strength welding wire for aircraft, ships and rockets

Rosatom is mastering laser welding using a collaborative robot