ODK-Saturn has begun manufacturing parts for the latest PD-8 aircraft engine on unique domestic machine tools. This was reported by the company's press service.

The new equipment has no analogues in Russia and automatically performs two operations at once.

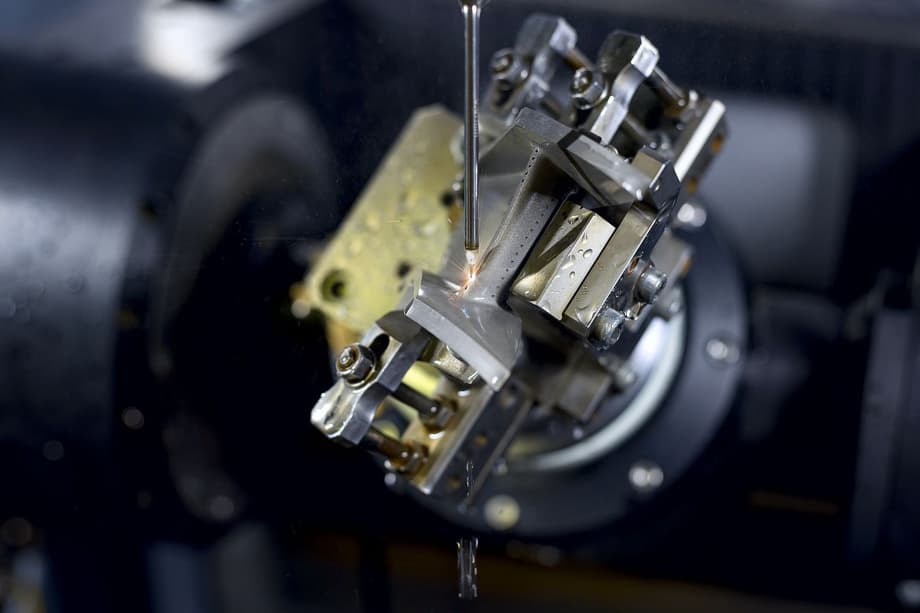

The new equipment combines electrical discharge and laser functions. This reduces the production time for PD-8 engine blades.

Today, the company has four modern machine tools, and four more are planned for delivery in the near future. The operation of the units is already effectively organized around the clock.

The Russian hybrid laser-erosion unit allows creating perforation holes in nozzle and working turbine blades. These holes provide a "film cooling" effect, which further protects the blade from high temperatures. This improves the reliability and durability of the engine.

Earlierwww1.ru reported that ODKrevealed the technology of "growing" blades for PD-8 and PD-14 aircraft engines.

Read more on the topic:

A unique laboratory for testing PD-8 and PD-14 aircraft engines was opened at ODK

The most difficult moments in the development of the Russian PD-8 aircraft engine have been named

ODK has transferred additional PD-8 engines for Superjet certification