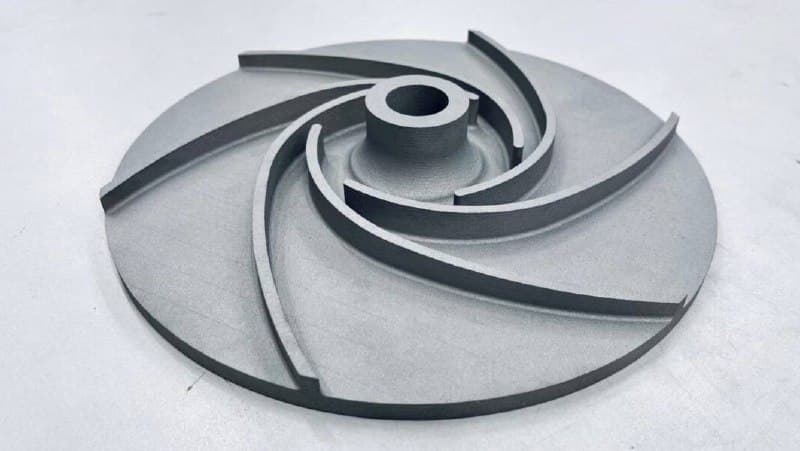

Rosatom State Corporation has created a pump impeller for the sublimation production of the Siberian Chemical Combine. The production used selective laser melting technology on a RusMelt-300 3D printer. This was reported by the state corporation's press service.

This is the first time that a product manufactured using 3D printing has been used at a nuclear facility, and it will be further proof of the high quality and reliability of additive manufacturing of parts and components.

It is worth noting that the RusMelt-300 3D printer was also developed and manufactured by specialists from Rosatom State Corporation.

Earlier, www1.ru reported that Rosatom had for the first time developed nuclear fuel for a reactor in Bolivia.

Read more on the topic:

Three months left: Kursk NPP-2 is preparing to launch a reactor

Neutralized by 60%: Rosatom is reclaiming the Krasny Bor toxic waste landfill near St. Petersburg

Now on home

Герой России Гарнаев: никто из профессионалов о возобновлении производства на КАЗ всерьёз не говорит

Система отслеживает спутники на высотах до 50 000 км и ведёт за ними наблюдение

The armored vehicle is equipped with a KamAZ-740.35-400 diesel engine with a power of 400 hp.

Constant improvements in avionics, weapons and tactical capabilities will make the aircraft a flexible response to future challenges

The exterior of the KamAZ-54901 features fairings on the cab and chassis for fuel economy

Fighters are in demand both domestically and abroad

Tyazhpromexport and Venezuela Agree on Plant Revival

The company not only completed the state order, but also quickly mastered the production of AK-12K for special forces

Experts have developed a photogrammetric complex with a resolution of less than 1 cm