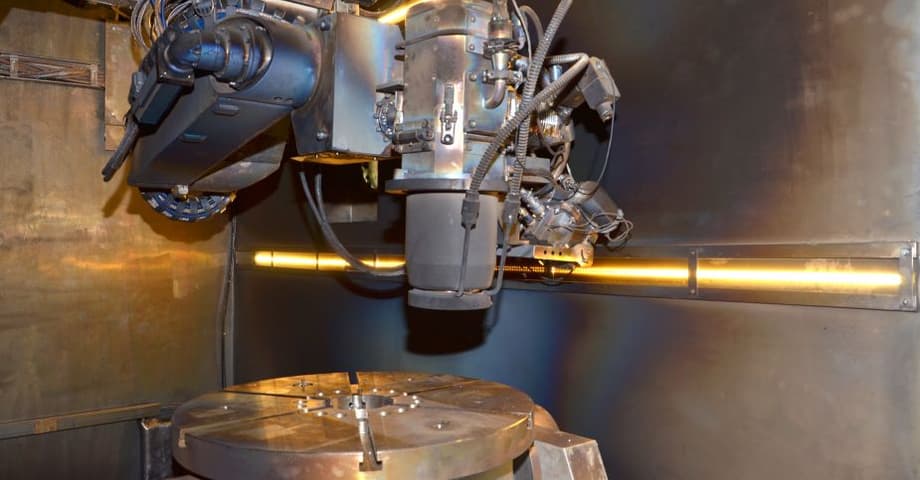

The Research and Technological Institute "Progress" (managed by the "RT-Capital" management of the "Rostec" company) has developed and patented a new solution in the field of electron beam surfacing. Electron beam welding melts metal wire and forms the necessary parts, like a 3D printer. They are stronger and more resistant to corrosion than their counterparts made in other ways.

This printing method provides high accuracy and repeatability of results, which is important in mass production in various industries, as well as in the repair of damaged parts. The key element of the new technology is a special module that feeds the wire under the melting beam from any direction. This allows growing complex parts with high precision. A similar module, but for argon-arc welding, has already been tested for projects in the nuclear industry and has proven itself perfectly, especially in confined spaces. The technology has been patented.

The new module can be installed on any robotic welding complex of NITI "Progress", complementing its functionality with printing and repairing parts. In the near future, the operation of the welding module will be automated and separate special software will be developed for it.

Read materials on the topic:

A new test bench for piston hydraulic cylinders has been created in Russia

Russia is considering how to extract 15% of the world's titanium reserves from its subsoil

A new type of aircraft wing with a movable skin has been created in Russia

Now on home

The service contains data on 45,000 fraudulent sites

The state has accelerated the introduction of unmanned solutions, integrating them into the real sector of the economy

Modernized engines may equip the Lada Azimut crossover

The price is 132 billion 265.8 million rubles

The manufacturer plans to strengthen its lineup of light commercial vehicles

The production of carbon fiber was organized in the shortest possible time

Electric vans will speed up the repair of urban transport infrastructure

Countries are working to synchronize regulations in the field of AI

The service's average daily audience is 55 million people

Stable Isomaterial Based on Metakaolin Has a Density Below 300 kg/m³

Re-identification quality improved twofold with new DynaMix method

Russians will be able to find out about debts online