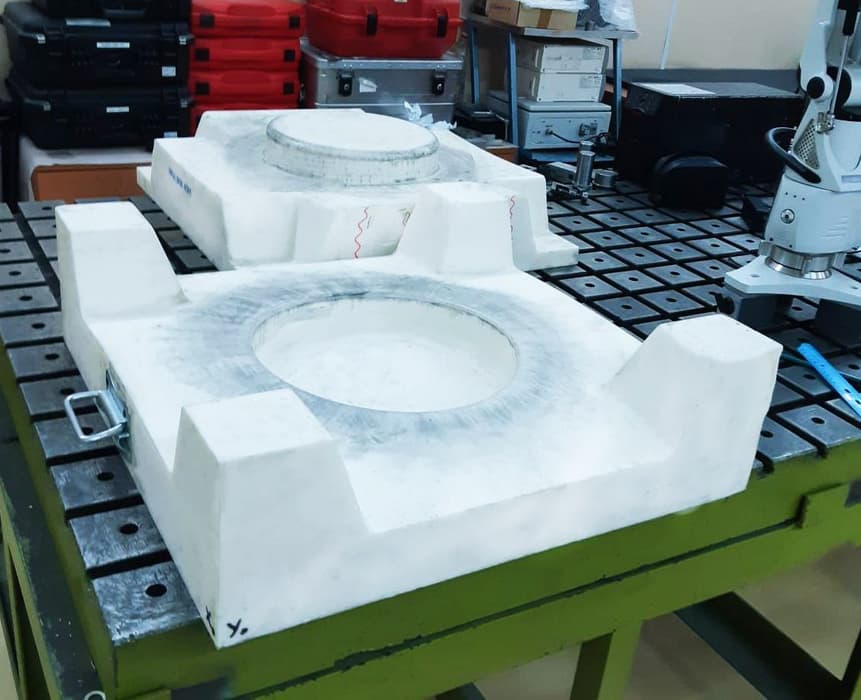

Specialists of the branch of PJSC Il - Aviastar (part of UAC) in Ulyanovsk use modular 3D tooling (a device for fixing workpieces, assembly) for the production of aircraft parts. This tooling is made of composite materials and replaces the traditional one.

The UAC press service explained that modular tooling is created using additive technologies (3D printing). It has all the functions of classic tooling and withstands loads.

Advantages of the new generation tooling:

- increased labor productivity

- reduction of terms of constructive and technological preparation of production

- reduction of material consumption

- efficient use of production areas

For example, in the die tooling shop, instead of lead-zinc dies, dies were made of impact-resistant composite materials.

Their mass is many times less, which allows placing die tooling on stackers

The OK added that specialists from the Competence Center "Technology of Composites" of the Institute of Aviation Technologies and Management of UlSTU were involved in the manufacture of 3D tooling.

At PJSC Il - Aviastar in Ulyanovsk, heavy transport aircraft Il-76MD-90A are assembled for the needs of the Russian Ministry of Defense. The department set the task to increase the output of military and civilian aircraft.