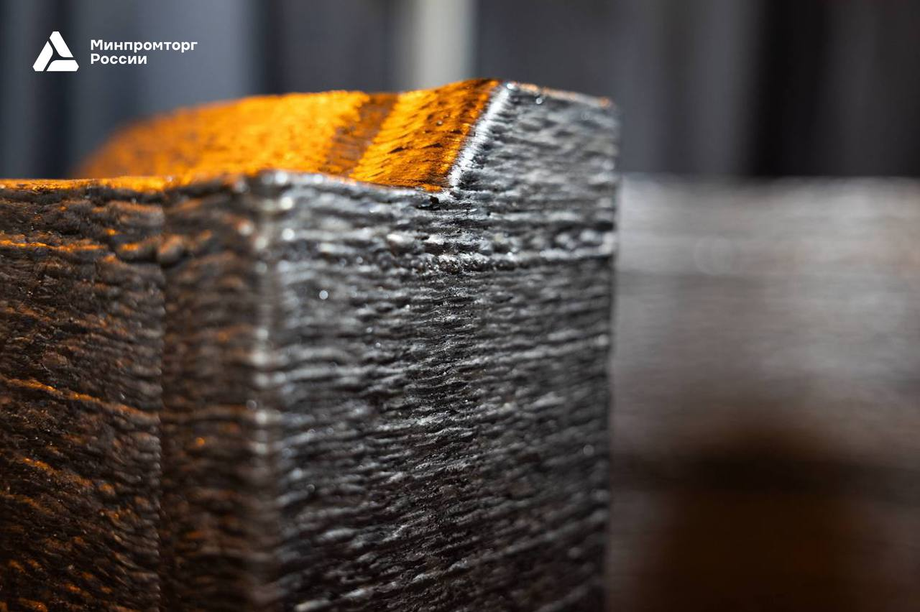

"Power Machines", in collaboration with scientists from Peter the Great St. Petersburg Polytechnic University (SPbPU), announced a significant achievement in the field of domestic power engineering. The partners managed to develop and implement a robotic complex that allows manufacturing large-sized parts using the electric arc growing method. The result of the work was a blank for a steam turbine sealing ring, the weight of which exceeded 750 kg. The indicator is considered an absolute record for the Russian industry.

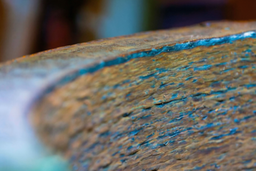

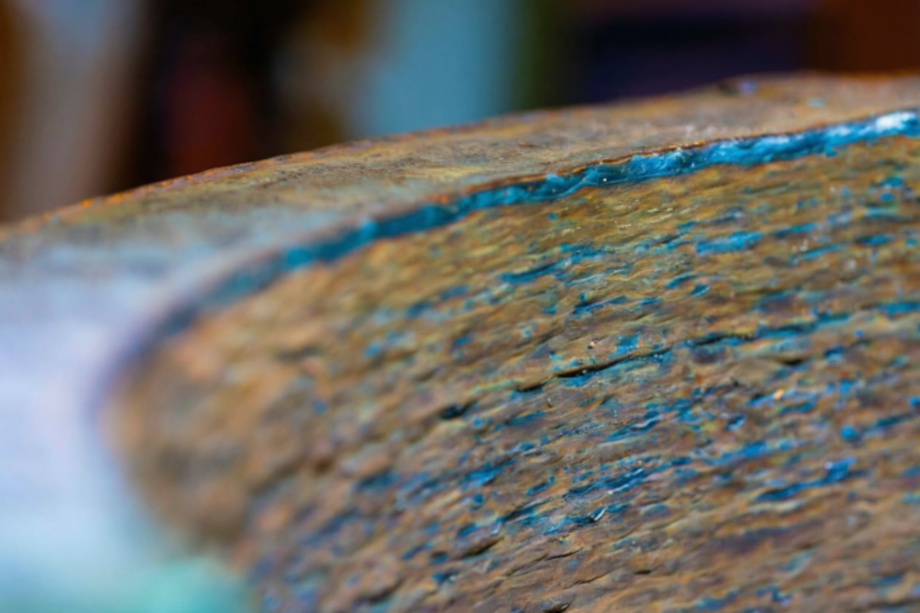

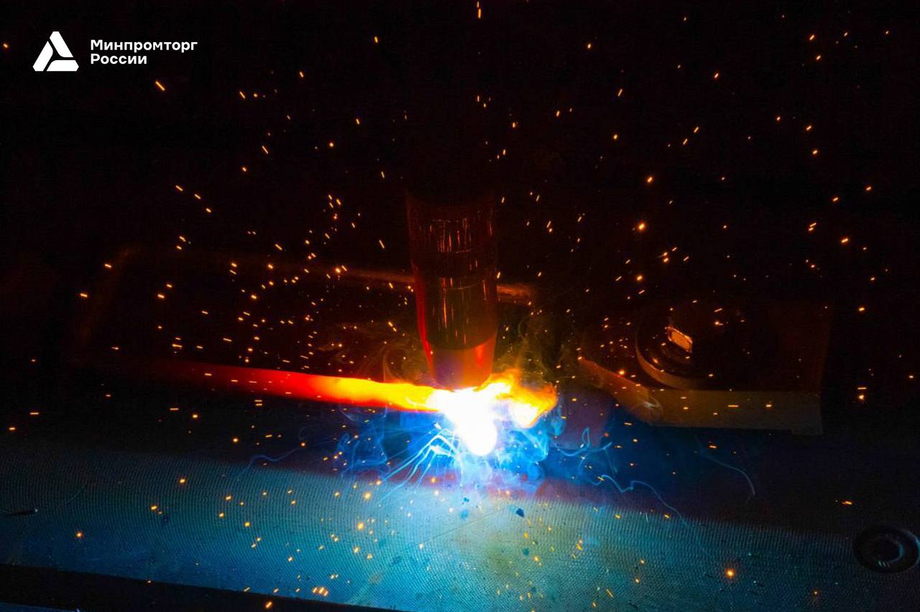

The innovative process is based on Wire Arc Additive Manufacturing (WAAM) technology, adapted by enterprise specialists to solve the problems of heavy engineering. The technological cycle involves layer-by-layer surfacing of metal using special wire. The process is controlled by an industrial robot, which ensures high positioning accuracy of the burner.

Representatives of the holding noted that the width of the printed layer in the developed technology reaches 201 mm. This parameter significantly speeds up the process of forming the volume of the part compared to traditional methods of additive manufacturing, where the surfacing thickness is usually much smaller.

The press service of "Power Machines" emphasized that the use of the electric arc growing method makes it possible to implement engineering solutions that are difficult or impossible to implement with classic casting or forging.

In the future, the technology can be used to manufacture other critical parts of turbines and generators, where high performance characteristics and complex geometry are required.