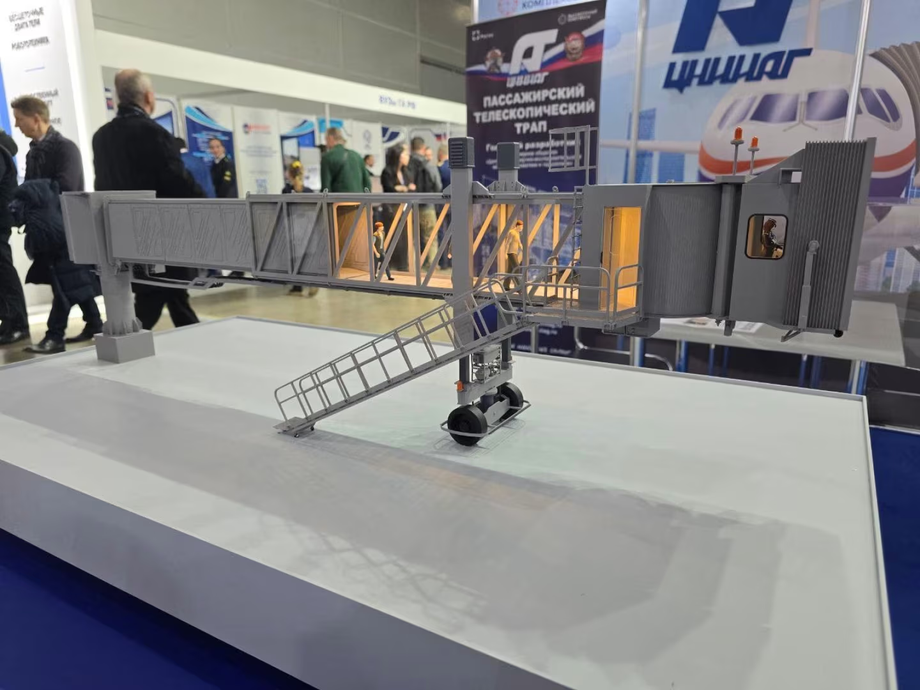

The "High-Precision Systems" holding (part of Rostec Group) has successfully conducted preliminary tests of the first Russian passenger boarding bridge, developed jointly with NPP "Proekt-technika". The prototype confirmed the stated characteristics.

Previously, such equipment was supplied to Russia only from abroad. The new "sleeve" is equipped with special electromechanical and electro-hydraulic drives, a control and safety system, which allows it to change height, length and configuration when docking with an aircraft.

Thanks to this, the passenger boarding bridge is compatible with all types of aircraft - from regional aircraft to long-haul airliners.

The product is highly reliable and meets the most stringent safety standards that apply to passenger boarding bridges.

Earlier www1.ru reported that ODK-Klimov Revealed All Stages of Aircraft Engine Production for Il-114-300 and Ansata.

Read more materials:

Russian Tires for MS-21 and SJ-100 Aircraft Chassis Successfully Certified

Deadlines Pushed Back Again: Il-114-300 Will Only Receive Certification in 2026