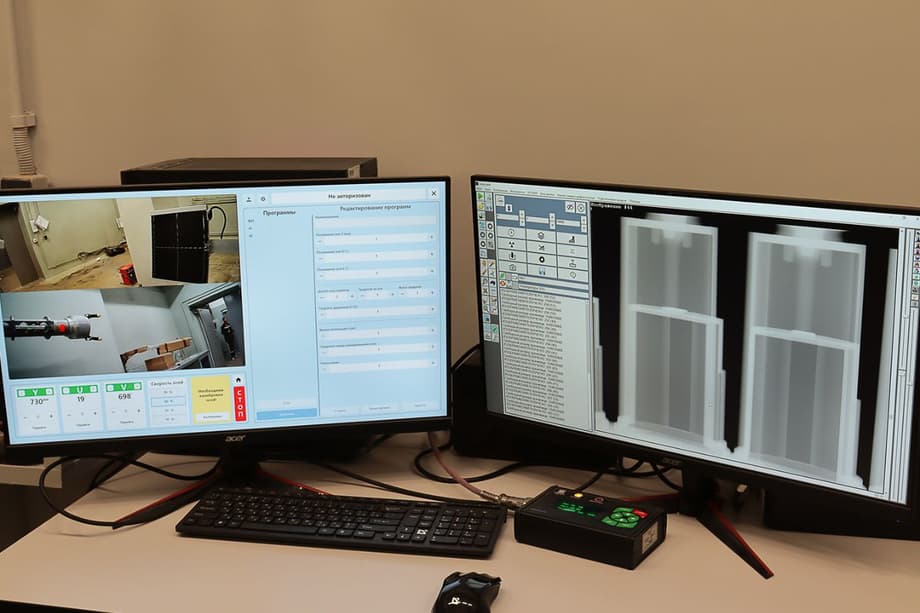

A new X-ray complex, manufactured in Russia, has been installed at the Kirov Mayak plant (part of the Kalashnikov concern). The equipment will replace outdated photographic plates, which could not effectively detect small internal damage and required a lot of processing time.

The new X-ray machine allows for quick and accurate diagnosis of parts, transmitting high-quality images to the screen in real time. Thanks to this, employees significantly reduce inspection time and reduce the risk of errors.

Anastasia Sitnikova, an X-ray and gamma-ray operator, notes that the new equipment helps to detect even minor defects, such as microcracks. The use of new equipment increases the level of safety and reliability of products.

The introduction of the X-ray complex is an important step towards improving the quality of products and increasing the competitiveness of the Kirov Mayak plant.

Read more on the topic:

Stereo X-ray technology developed in Russia

MISIS has developed a detector that can detect inflammation through clothing

AI algorithms can create unique devices for inspecting large equipment