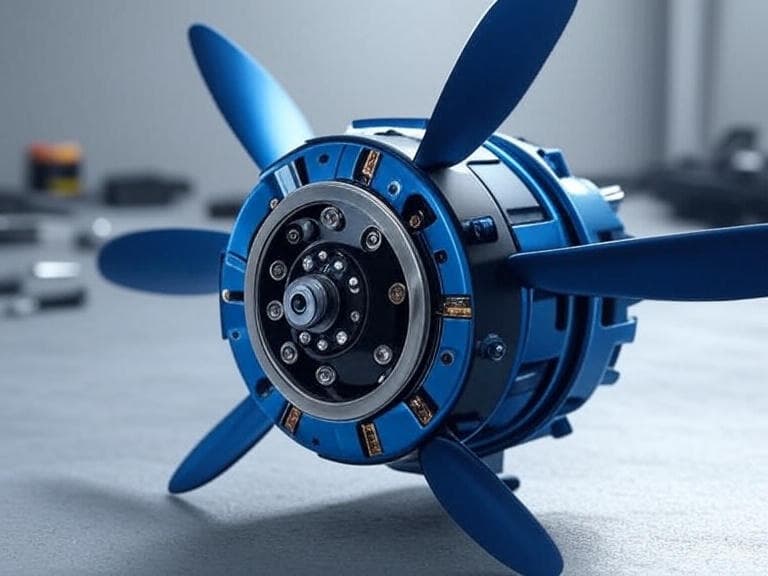

A domestic electric motor for drones with a take-off weight of up to 30 kilograms has been developed in Novosibirsk, with a production localization level of 95%. This was announced by Nikita Boikov, General Director of the Aviator Research and Production Association.

We have developed an electric motor for a drone. It is designed for a UAV with a take-off weight of up to 30 kg. Production is localized here in Novosibirsk, 95% is domestic material content. In terms of frequency regulators on a domestic component base, we are the first in the country to start doing this.

The electric motor is equipped with a frequency regulator that changes the frequency of the electrical energy supply, allowing smooth control of the engine speed and reducing energy consumption, especially in systems with variable loads. In some characteristics, the new motor is comparable to Chinese counterparts, and in some aspects even surpasses them.

The device was created using exclusively Russian materials, including steel, copper, connectors, and glue. Neodymium magnets were used from foreign sources, which are necessary to create a strong permanent magnetic field with small size and weight of the device.

The Aviator company has already begun supplying new motors to drone developers and has organized small-scale production.

Currently, we can make about 100-200 motors per month. As soon as we have a corresponding order, we will make a large batch.

Earlier, www1.ru reported that the production of engines for drones will be established in Krasnoyarsk.

Read more on the topic:

China is no longer needed? Russian drones will be equipped with domestic engines

"Sarma", "Khius", "Barguzin", "Kultuk": Rostec has developed a line of engines for drones

Testing of "Hummingbird" engines for jet drones has begun in Samara

Now on home

The power unit is installed on patrol and border boats

KAMAZ-740 V-shaped diesel and KAMAZ P6 six-cylinder engine are being considered as options

Mishustin: Certification of the Russian medium-range aircraft completed

All 20,000 Pieces Were Purchased with Funds from Concerned Citizens

Analyst Vladimir Leonov was surprised by the delivery times of the regional airliner

The payload capacity of the new product is 35 tons, power take-off is provided for driving the drum

Chairman of the Marine Board of the Russian Federation pointed out the shortage of necessary components

The price of an unusual car is 1.5 million rubles

The multiple launch rocket system's salvos have become even more accurate

In dry form, such an energy source can be stored for years without losing its properties

New protective materials withstand 950 °C, extreme wear, and will help in mechanical engineering