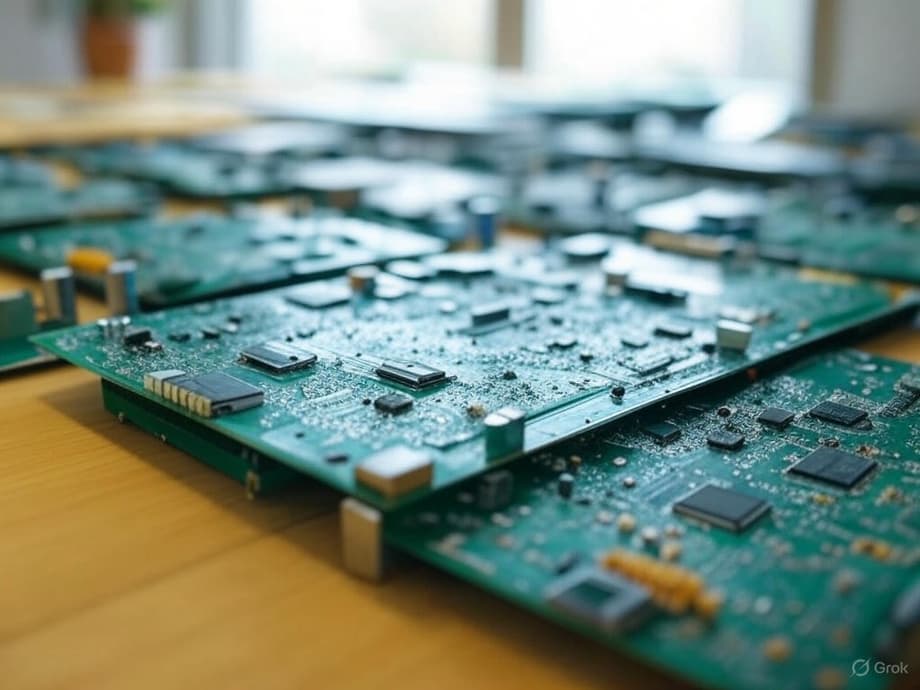

A mini-factory for the production of multilayer printed circuit boards, which are used in modern electronic devices, has been developed at the Russian Technological University (RTU MIREA). This was reported by the university's press service.

The new mini-factory uses several 3D printing technologies and combines traditional ceramic processing methods with additive technologies. This significantly reduces prototyping time and increases production efficiency.

The prototyping stage allows you to test the idea, circuit and installation of the device. If traditional approaches require several weeks to create a prototype, 3D printing will take from 30 minutes.

The process of creating printed circuit boards includes the synthesis of a special polymer-ceramic material, 3D printing, filling with conductors and firing. Depending on the specific tasks, high-temperature and low-temperature types of ceramics are used. This ensures the strength and stability of finished products.

Our development allows us to significantly reduce the cost and speed up the production of ceramic boards, while maintaining their high performance characteristics. This is especially important for the creation of modern electronic devices, where reliable and compact components are required.

Earlier www1.ru reported that manufacturers proposed to make Russian boards mandatory in electronics.

Read materials on the topic:

One story high: the largest military printed circuit board in Russia was manufactured in Yoshkar-Ola