Specialists from Tomsk Polytechnic University (TPU) have developed embedded software and an automation system for a new generation ultrasonic tomograph. The equipment is designed to control the quality of elements of the world's first international thermonuclear reactor ITER, which is under construction in France. A prototype has already been handed over to the customer - JSC "NIIEFA named after D. V. Efremov" (part of Rosatom).

The tomograph functions as a laser 3D scanner, optimizing ultrasonic non-destructive testing. The system automatically determines the position of an object in space using laser calibration, which is critical for working with elements of complex geometry. The preparation time for testing has been reduced from several hours to 5 minutes, and a full cycle - from scanning to protocol formation - takes no more than 4 hours.

Previous methods required manual adjustment for each object. Our development eliminates the human factor, increasing speed and accuracy by several times

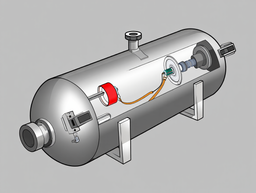

The tomograph will be used to inspect the first wall of the ITER reactor - a key element subjected to extreme temperature and radiation loads. The device is made mainly of domestic components, including an immersion bath, a robotic manipulator, and a safety system.

Read materials on the topic:

New tomograph for quality control of aviation parts developed in Russia

Creation of tomographs and sensors of the future accelerated in Moscow

Will increase the accuracy of assessing mineral reserves: Rosatom has developed a new muon tomograph