An eco-friendly method for creating materials with increased corrosion resistance has been developed at Saratov State Technical University (SSTU), the university's press service reported.

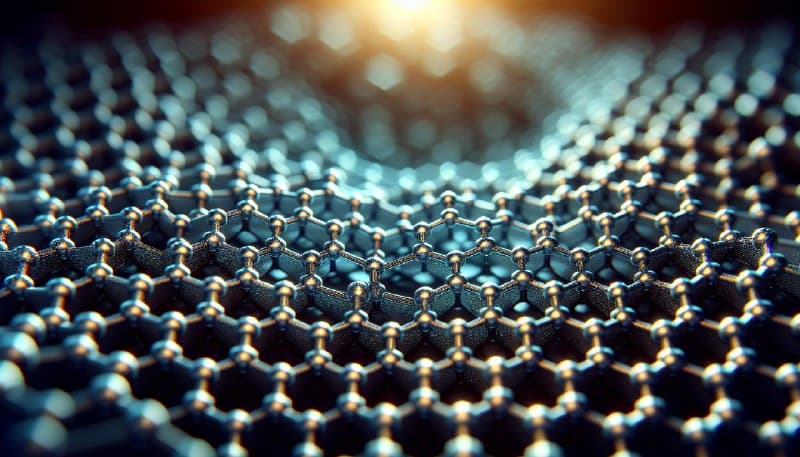

The main advantage of the new method is the absence of strong oxidizing agents, which makes the process more environmentally friendly. In addition, electrochemical oxidation results in a more uniform filling of the interlayer spaces of graphite with an intercalate, and therefore, compounds with homogeneous properties are formed.

Now, specialists will be able to produce polyraphene materials in significant volumes.

The material based on multilayer graphene oxide is multifunctional. It can serve as an alternative to a sulfuric acid-based catalyst in the process of fine organic synthesis, providing a reduction in reaction time by 1.5-2 times.

The resulting graphene oxide will improve the microhardness of structural elements and increase their corrosion resistance.

Earlierwww1.ru reported that in Novosibirskplasma and laser technologies were created for aircraft repair.

Read materials on the topic:

New metal cutting technology for aircraft parts launched at PJSC Il - Aviastar

New engines developed for long-range aviation aircraft of the Russian Aerospace Forces

MAI has created a technology to protect aircraft skin from icing

Now on home

Netizens believe that UAVs are better replaced by thousands of small satellites at an altitude of 200 km

Likhachev: We are ready to offer Serbia the entire range of our projects

Fraudsters have learned to imitate the interface of a bank and payment system

The truck can operate as part of road trains weighing up to 100 tons

Work on the high-speed maglev body has already begun

The first stages of the program are planned to be completed by 2032

Recovery teams are working at the scene

The fifth prototype was accelerated to 190 km/h at an altitude of 300 meters

Over the past two years, the growth rate in this segment has been at 15%

Experts got acquainted with the key objects of the experimental base and advanced methods of certification flights

In annual reports, parliamentarians willingly share statistics from their channels

The university is also working on creating robotic manipulators and robotic welders