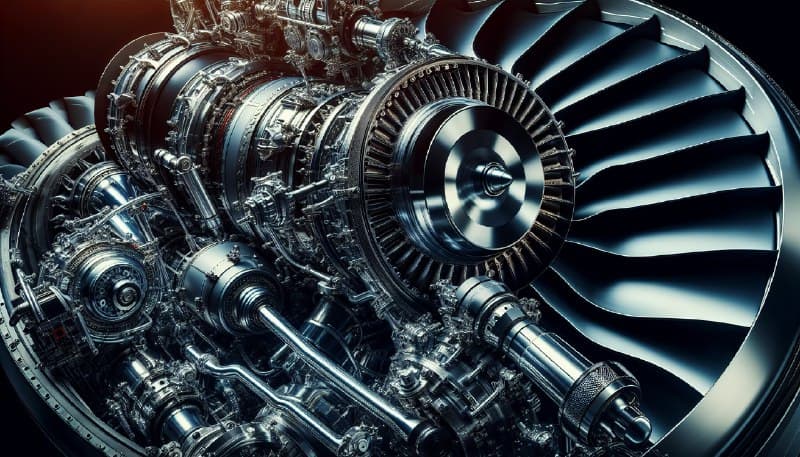

At the Yuri Gagarin State Technical University of Saratov (SSTU), a high-strength die was developed for the production of aircraft engine blades. This was reported by the press service of the Ministry of Education and Science of the Russian Federation.

We were able to create a die with improved quality and operational reliability characteristics, which can significantly extend the service life of die equipment in production, minimizing the need for frequent repairs or replacements.

Existing die designs for the aviation industry suffer from insufficient mechanical strength of the engraving surface of the upper and lower inserts. This leads to their deformation and destruction during blade stamping.

The technology of hardening the working surfaces of the die is an effective method of increasing the wear resistance and durability of tools. Scientists have achieved a reduction in the wear of die inserts due to laser cladding of a high-strength nanostructured coating made of a two-component mixture of titanium carbide and boron carbide powders.

Earlier, www1.ru reported that Rostec for the first time presented the latest 177S aircraft engine for combat aviation.

Read materials on the topic:

Unique footage: the first image of the second stage engine AL-51F1 for the Su-57 fighter

Now on home

The service contains data on 45,000 fraudulent sites

The state has accelerated the introduction of unmanned solutions, integrating them into the real sector of the economy

Modernized engines may equip the Lada Azimut crossover

The price is 132 billion 265.8 million rubles

The manufacturer plans to strengthen its lineup of light commercial vehicles

The production of carbon fiber was organized in the shortest possible time

Electric vans will speed up the repair of urban transport infrastructure

Countries are working to synchronize regulations in the field of AI

The service's average daily audience is 55 million people

Stable Isomaterial Based on Metakaolin Has a Density Below 300 kg/m³

Re-identification quality improved twofold with new DynaMix method

Russians will be able to find out about debts online