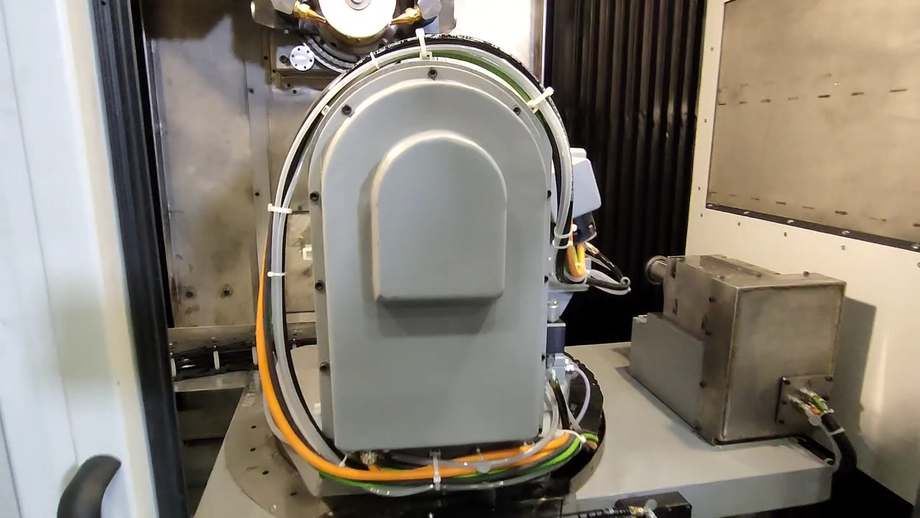

The STAN holding (part of the Rostec Group) has started producing the SXS 410 OC multi-functional processing center. This was reported by the company's press service.

The device allows processing a turbine blade of the engine in one pass, including the lock (the most complex component of the product).

The machine is designed for processing flat and shaped surfaces using highly porous grinding wheels and cubic boron nitride wheels with a minimum number of setups. Unlike standard abrasive wheels, the cutting speed of which is 15-35 m/s, cubic boron nitride tools allow reaching speeds of up to 60 m/s.

The machine design includes a three-axis rotary table. This allows processing workpieces in several passes with a minimum number of fixtures.

The equipment makes it possible to carry out both grinding and milling of products. The machine is planned to be used at enterprises engaged in the production and repair of aircraft engines.

Earlier www1.ru reported that Rostec developed a machine for testing steel aircraft ropes for endurance.

Read materials on the topic:

Roselectronics is developing a digital twin of airports

Rostec: SSJ 100 engine will be installed on a flying laboratory

Rostec showed how parts for Il-96, Il-76, MS-21 and SJ-100 are hardened