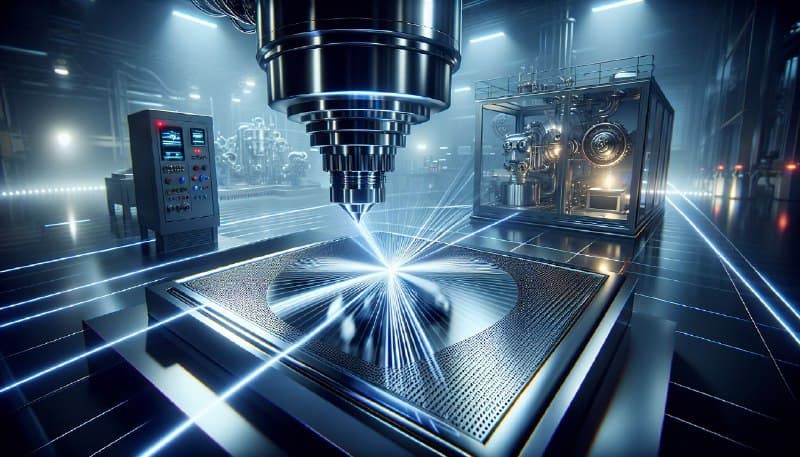

The Inject Research and Production Enterprise (NPP) has developed a PLD-6 technological laser to increase metal wear resistance. This was reported in the press service of the Ministry of Industry and Energy of the region.

The new laser has no analogues in Russia or abroad.

With its help, Saratov engineers increase the wear resistance of metal in the hardened zone by 1.5-3 times. The surface hardness of parts made of 40X steel, after laser hardening, increases from 12 HRC to 58 HRC.

The development is planned to be used in agriculture, mechanical engineering and the railway industry. The new metal hardening technology will increase the service life of parts (drive shafts, gears) and the edges of cutting tools (plows, harrows, knives).

Earlier, www1.ru reported that in Tomsk synthesized ultra-pure titanium diboride.

Read materials on the topic:

Russia has developed a super-light aluminum-scandium alloy for civil vessels

Russian high-strength welding wire developed for aircraft, ships and rockets

Now on home

Герой России Гарнаев: никто из профессионалов о возобновлении производства на КАЗ всерьёз не говорит

Система отслеживает спутники на высотах до 50 000 км и ведёт за ними наблюдение

The armored vehicle is equipped with a KamAZ-740.35-400 diesel engine with a power of 400 hp.

Constant improvements in avionics, weapons and tactical capabilities will make the aircraft a flexible response to future challenges

The exterior of the KamAZ-54901 features fairings on the cab and chassis for fuel economy

Fighters are in demand both domestically and abroad

Tyazhpromexport and Venezuela Agree on Plant Revival

The company not only completed the state order, but also quickly mastered the production of AK-12K for special forces

Experts have developed a photogrammetric complex with a resolution of less than 1 cm