The BARS project (also known as "Fialka") was conceived as a unique aircraft combining the properties of an airplane, helicopter, and airship. Engineers sought to create a super-heavy platform with vertical takeoff capability through aerostatic unloading - compartments filled with light gas were intended to compensate for a significant portion of the structure's mass.

Conceptually, BARS was not just an experiment but an attempt to create a new class of aircraft for cargo, passenger, and special tasks. Variants with different payload capacities were developed - from transport platforms to fire and passenger modifications.

Results of Early Model Tests

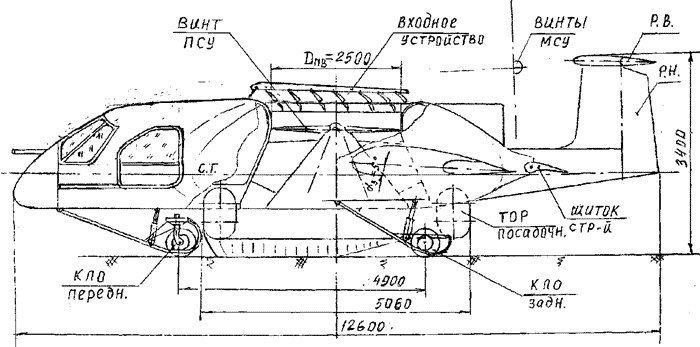

The first large-scale 2-seater model, "BELLA-1," was tested in 1995. Fifteen years later, in 2010, a new 5-seater version, "BELLA-1-2/4," began taxiing. Although these aircraft did not have aerostatic unloading and were equipped with a relatively weak central engine, they were used to test critical takeoff and landing modes.

The engineering materials accompanying the early modifications of "BELLA-1" and "BELLA-1-2/4" noted that the developers used a central power plant of aviation type, designed to ensure a safe short takeoff and landing mode. The engine operated a fixed-pitch propeller fan and provided stabilization of airflows along the longitudinal axis of the aircraft. However, its power was only sufficient to demonstrate the scheme, but not to implement a true vertical takeoff.

The project documents indicated promising solutions: the installation of a more powerful turboshaft engine, the transition to a multi-fan distributed thrust scheme, and the integration of aerostatic unloading circuits. Extended centerplanes, load characteristics of the frame truss, expanded fuel tanks, and hybrid power options were being developed to increase hovering time. In the final calculations, BARS was considered as an aircraft with a cruising speed of about 180-220 km/h, a payload of 1 to 10 tons (depending on the version), and a calculated flight altitude of up to 3-4 thousand meters, which made it competitive in the niche of heavy VTOL platforms.

Industry Distrust

The doubts of industry representatives - especially TsAGI specialists - ultimately greatly hampered the project's development.

The 10-seater passenger model "BELLA-2" could have been a decisive step, capable of dispelling doubts about the feasibility of the project, but its creation stopped at the stage of the second prototype.

Project Reflection

In a number of Russian aerospace and engineering publications, the BARS project was described as one of the most ambitious examples of private or low-budget aircraft construction initiatives. The authors emphasized that the work on "Fialka" demonstrates a high level of independent aerodynamic school: the designers competently combined lightweight materials, a non-trivial layout, and hybrid lift principles. Technical specialists noted that such projects rarely reach the stage of full-fledged testing, as they require non-standard calculation approaches and complex certification.

Other publications focused on the possibilities of using the aircraft in remote regions of Siberia and the Far East. Journalists pointed out that the combination of vertical takeoff and high payload capacity could change the transport map of Russian territories, especially in the fields of geology, the Ministry of Emergency Situations, and northern transportation. In essence, BARS was seen as an alternative to expensive helicopter technology for transporting oversized cargo and personnel.

The Project Needs Time

Despite dozens of newspaper publications, issued patents, the willingness of a number of departments to consider the use of BARS in reality, and decades of engineering work, the project never received the support necessary to reach a new level.

It seems that 35 years is indeed too little to appreciate an aircraft that was ahead of its time. Perhaps the future - the era of green energy, low-noise hybrid aircraft systems, and global demand for economical VTOL - will give the ideas of BARS a chance to unfold.

Read more materials:

- AV-112-114 propeller for Il-114-300 aircraft confirmed compliance with airworthiness standards and received a type certificate

- UAC analyzes the needs of the aviation market in preparing the operation program for the Il-114-300 aircraft

- Irkutsk Aviation Plant puts into operation a new building for the production of MS-21

Now on home

In dry form, such an energy source can be stored for years without losing its properties

New protective materials withstand 950 °C, extreme wear, and will help in mechanical engineering

VASO confirmed that the runway extension is part of the wide-body aircraft production

The device is powered by an AMD Ryzen AI MAX+ 395 processor with integrated AMD Radeon 8060S graphics

The use of ammunition increased the speed of combat operations of the "Msta-S" howitzers

The "KUB-10ME" Device Received an Optoelectronic Guidance System

New turbojet engine will change the approach to supersonic flight without classic afterburner

Foreign delegation visited the "Parus electro" electrical equipment manufacturing plant

"The new system is more powerful than the existing version"

Sergey Marzhetsky stated that placing orders in the DPRK could become a realistic solution under sanctions

NDTV: India Aims to Acquire 40 Combat Aircraft

The autonomous platform can travel up to 60 km