Russian engineers have devised a new design for a tank gun barrel with a thickened multi-layered casing. The development enhances the barrel's protection against fragments, climatic influences, and reduces the risk of deformation during firing. The patent was registered in the FIPS database in January 2026.

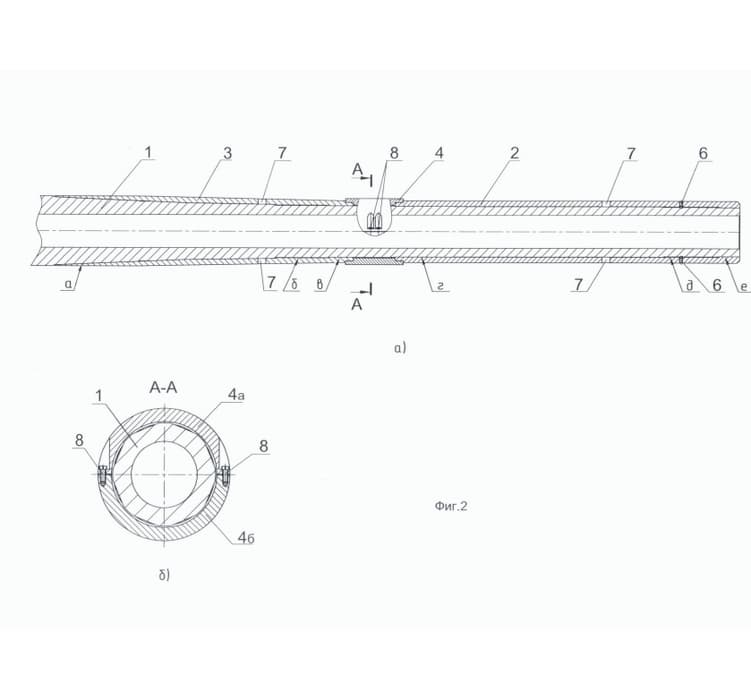

The submitted documents reveal that the prospective tank gun barrel features a two-section casing with a central spacer. The design includes screw-on attachments secured with stoppers and an additional section that ensures centering along the entire length of the barrel.

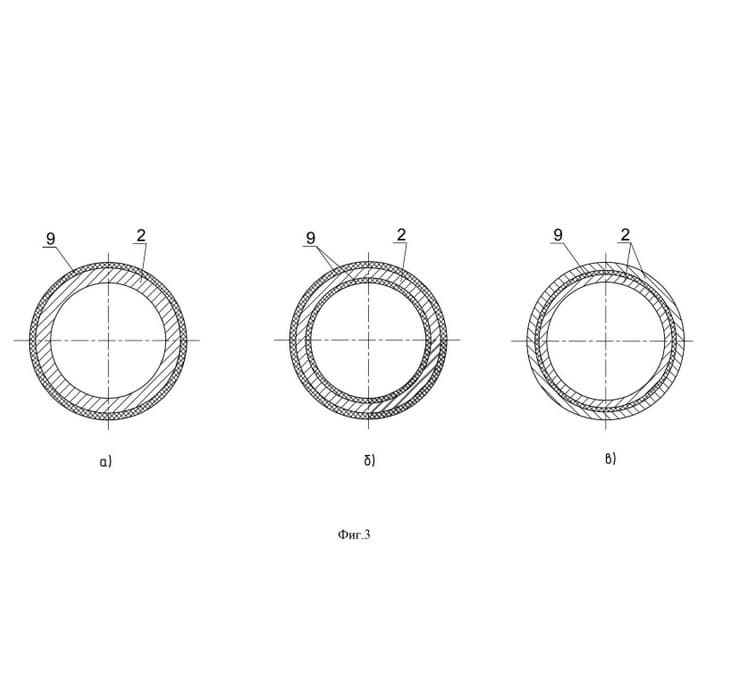

The casing is proposed to be thickened, with a multi-layered structure. Several variants use armor-resistant steel and reinforcing materials, including Kevlar fiber. A small gap is left between the casing and the barrel for temperature stabilization.

Currently, in combat conditions, the outer surface of the barrel is subjected to impacts from fragments, temperature fluctuations, and moisture exposure. Damage leads to microcracks and reduced accuracy. The new design reduces the risk of barrel bending, minimizes the impact of uneven heating, and extends the service life of the gun.

Interestingly, the casing includes technological openings for installation and removal. The central spacer can be made detachable — from two half-rings, to quickly replace damaged elements without completely disassembling the gun.

Read more on this topic:

Now on home

New fluorine production capabilities eliminate technological risks in the uranium transformation stage before enrichment in centrifuges

RIF company sued Krasnogorsk plant named after S. A. Zverev

The space complex will allow the development of the Earth's satellite's circumpolar regions

They found out how microplastics enter the lake's food chain

Its operation is based on brain reactions when looking at flickering light sources

New equipment will require at least 5 billion rubles, and the costs will fall on the fishermen and buyers themselves

New design reduces the risk of barrel bending after prolonged use

Transmashholding and Kurchatov Institute have already started developing a compact reactor

The system shows flooded compartments and safe evacuation routes

Experts tested a closed steam system with recycled exhaust steam

Wide-body aircraft transports Cuban military personnel

Articles

-

Russian An-124 "Ruslan" Stuck in Canada for 4 Years and Accrues Millions in Fines

26 Jan 2026

-

Coaxial Propellers: How Counter-Rotation Increases Turboprop Engine Efficiency

25 Jan 2026

-

Kazan Aviation Plant Breaks Old System: Tu-214 to be Assembled Like Cars

25 Jan 2026

-

How Engineers and Technicians Are Paid Today in the Russian Aviation Industry: An Overview with Figures

24 Jan 2026