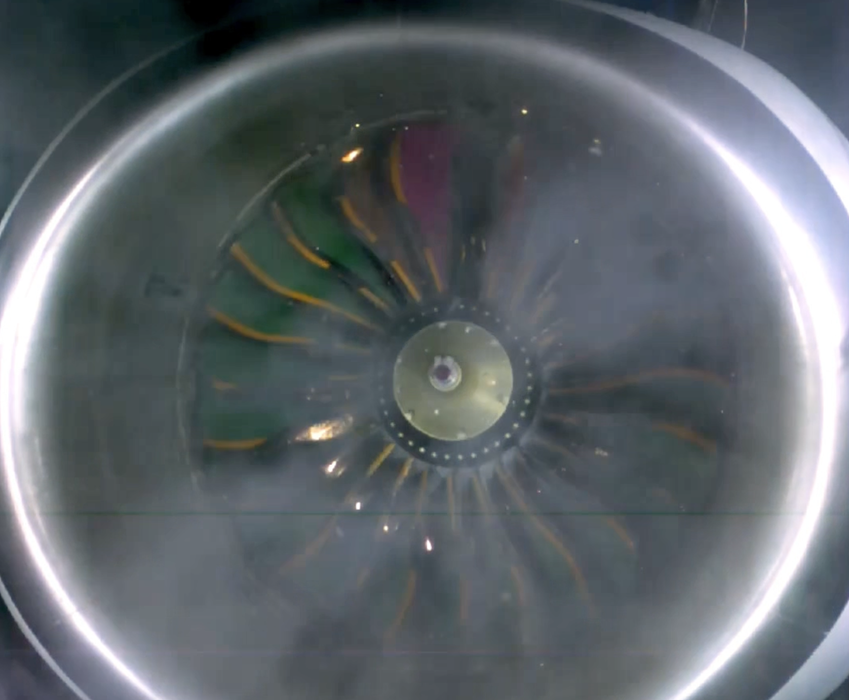

The United Engine Corporation (UEC, part of the Rostec State Corporation) has published impressive footage of tests of the new PD-8 aircraft engine. The video, filmed at the UEC-Saturn enterprise in Rybinsk, shows the moment when a controlled fan blade failure occurs in take-off mode — one of the most dangerous scenarios for any aircraft power plant.

The test confirmed the structural stability of the engine: despite the powerful impact, the fan casing remained intact, and no fragments left the engine. This is a key criterion of certification requirements — such incidents should not lead to damage to the fuselage and should allow the aircraft to safely complete the flight.

To check, the engineers built a pyrotechnic charge into one of the blades. After the engine was brought to take-off mode, the charge went off, causing the blade to break off, but the structure withstood the test.

Aleksey Veretennikov, Deputy General Designer for Testing at UEC-Saturn, noted that maintaining the integrity of the casing is the most important indicator of reliability and confirmation of the correctness of design solutions.

Before the experiment, specialists prepared the test bench, equipping it with a current collector, a phasing system, and air sampling. Measurements showed that even with this scenario, the level of oil vapor emissions into the air conditioning system remained within normal limits.

The PD-8 engine has already undergone a series of tests — tests for water ingress, acoustic tests, tests for stability in crosswinds and in reverse mode. All key tests were performed with a thrust of over 8,000 kgf.