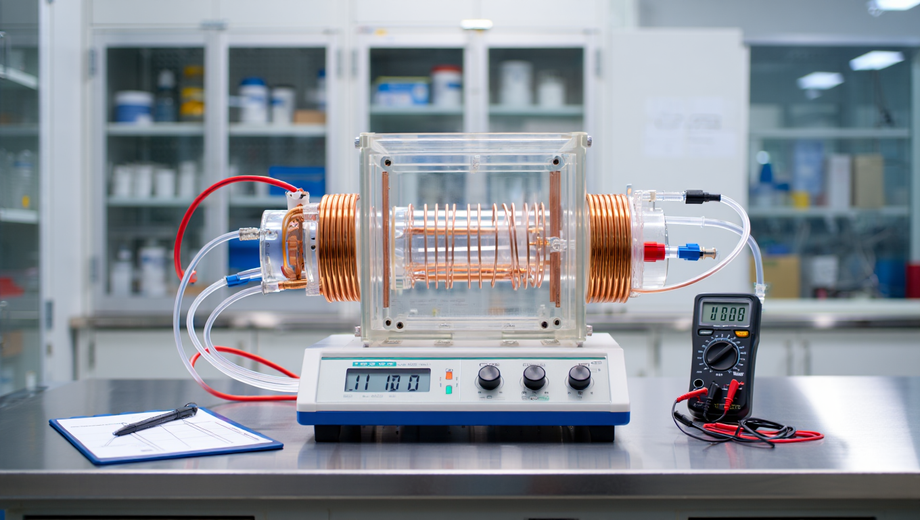

At the Nizhny Novgorod State Technical University named after R.E. Alekseev (NSTU), an innovative device for chemical equipment has been developed and patented, which ensures an increase in heat exchange efficiency by 20%. This was reported in the press service of the Ministry of Science and Higher Education of the Russian Federation.

The new development relates to the field of contact devices designed for carrying out heat and mass transfer processes in gas (vapor) - liquid systems. The device is especially effective in processes with moderate thermal effects accompanying sorption, chemisorption processes and rectification processes.

Vortex generators in the form of a spiral winding are integrated into the central pipe of the device. They structure the coolant flow and increase its speed. A horizontal partition is also installed in the pipe (manifold), which allows dividing the supply and removal zones of the coolant, which eliminates the formation of stagnant zones.

This device is designed for heat and mass transfer processes between gas (vapor) and liquid phases with high efficiency. The device can be used in the petrochemical, food and other industries. The development stands out for its simple design and manufacture.

Earlier,www1.ru reported that a cooling system with combined coatings for microelectronics wascreated at the National Research University "MPEI".

Read also:

- New Russian heating heat transfer measurement system will save up to 1 billion rubles per year

- A material based on nanotubes has been created in Russia to increase the efficiency of batteries in frost

- Will reduce losses from 7% to 38% - new containers for transporting liquefied natural gas have been developed at the Russian MAI