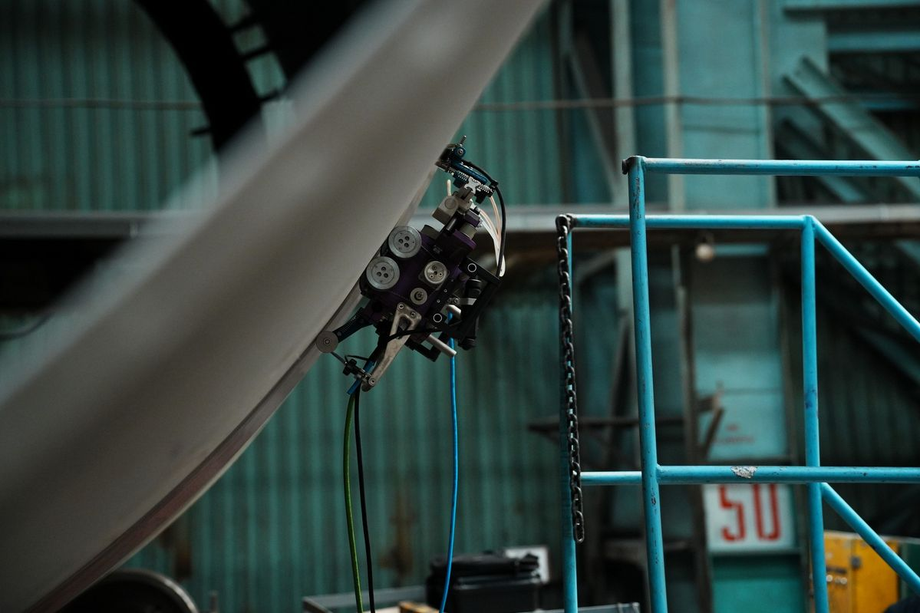

A robot designed to inspect welds in nuclear reactors has been put into operation at the Atommash enterprise. The spider robot is equipped with a new generation ultrasonic transducer that allows quality control of welded joints.

To make a qualitative leap in development, we must create products that will define the future. Digitalization is becoming the main tool in this. A modern factory is a place for innovation and the implementation of bold projects. The "Spider Robot" is a clear example of how technology serves the safety of nuclear energy.

Traditional methods of weld inspection required significant labor and time, and also implied the need for personnel to work in conditions of increased radiation. The new spider robot automates this process, minimizes risks for employees, and significantly increases the accuracy and speed of inspections.

The ultrasonic transducer with which the robot is equipped can detect the smallest defects and inhomogeneities in the metal structure of the weld with a high degree of reliability. The data obtained is transmitted in real time to the operator, who can assess the quality of the connection and decide whether it needs to be repaired or replaced. Thanks to the high mobility and adaptability of the design, the robot is able to move along the complex geometry of the reactor, ensuring complete coverage of all welded joints.

Earlier www1.ru reported that the particularly strong outer protective shell of the VVER-1200 reactor began to be erected at the Leningrad NPP-2.

Read more materials:

- Rostec proposed to significantly increase the capacity of the gas transportation system of Uzbekistan

- To repel possible drone attacks: a system of aerostat barriers using airships will be launched in Russia

- Combined braking of electric and pneumatic brakes was first introduced in Russia on the TEP-70BS diesel locomotive