A new ULTRAFLAME SBR-2060 plasma cutting machine, manufactured by specialists from the "SPIKOM" group of companies (Barnaul), has been put into operation in Tomsk. This is not the first instance of the series, which is gradually becoming a standard for Russian enterprises that need high-precision thermal processing of metal.

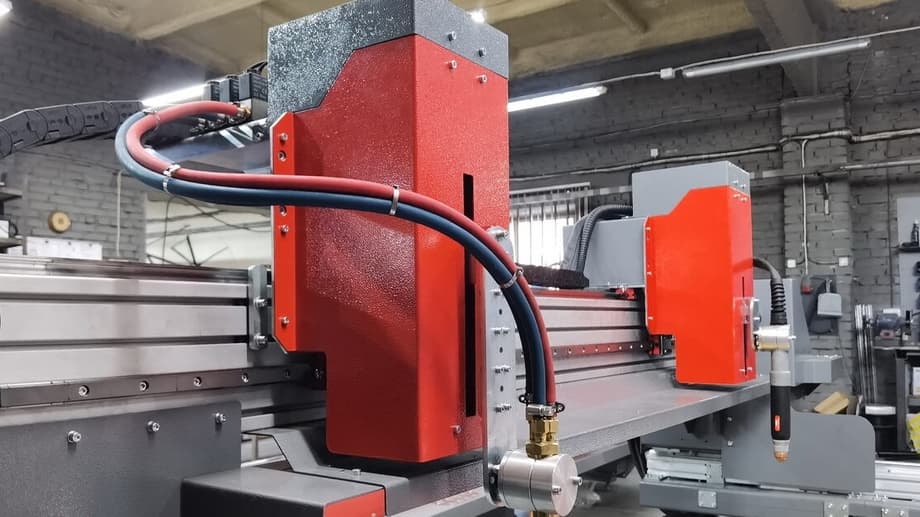

The machine is capable of processing sheets up to 2000×6000 mm in size and performs metal cutting up to 25 mm thick when piercing and up to 50 mm when cutting from the edge. The equipment is based on a KEDR MULTICUT-1200 plasma source. The portal structure is made of durable aluminum profile, and all mechanisms and gears are reliably protected by steel boxes from dust and damage. Thanks to this, the machine maintains accuracy and stability even during long-term operation.

An industrial controller with numerical program control (CNC) "SPM-7" with a Russified interface and "U-CUT" software is used for control. It supports working with popular AutoCAD and "Kompas" drawing formats, as well as SHEETCAM, PRONEST and TEKHTRAN cutting systems. Data is transferred via a USB connector, and the built-in parts library allows you to instantly cut standard shapes - from squares to rings.

SPIKOM engineers paid special attention to ease of operation. The control terminal is located directly on the portal, and the modular cutting table is equipped with a ventilation system and reinforced sections that can withstand loads of up to 2.5 tons each. The collapsible frame allows you to install the equipment without anchor fastening on almost any surface - this simplifies installation and makes the machine a universal solution for workshops of any scale.