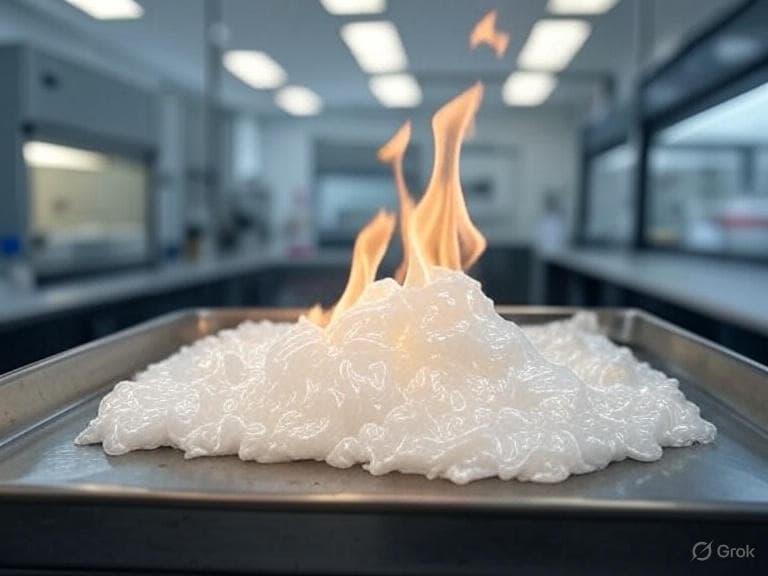

Scientists from the Kabardino-Balkarian State University named after H.M. Berbekov (KBSU) have developed a new technology for creating safe polyethylene. The new approach reduces the flammability and toxicity of the material.

The researchers proposed a magnesium-based additive that does not contain harmful components. When polyethylene with this additive is burned, toxic melt droplets are not formed, and the amount of smoke is reduced. This makes the material less dangerous to human health and the environment.

The introduction of the additive into the plastic is carried out using standard industrial equipment used for the production and processing of polymer composites, which simplifies its integration into production.

One of the main advantages is its practical applicability. Specialists used compounds that already exist on the market. This made it possible to implement the method without significant changes in production equipment.

The new additive improves the performance characteristics of polyethylene. It is easy to integrate into plastic using standard production equipment. This simplifies the technological process.

Earlier www1.ru reported that turning recycled polyethylene into durable industrial material has been learned at SevSU.

Read materials on the topic:

- Plastic recycling was optimized in Yekaterinburg using radiation

- In Novosibirsk, a building material based on recycled polymer waste was developed

- In Mordovia, a super-strong polymer was created from multilayer packaging waste

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation