Rosatom intends to create prototypes of silicon carbide fuel rod cladding by 2030 and fully introduce them into industrial production by 2045.

The deadlines are not shifting. The only change that has occurred is that we had to deal more extensively with the source materials for these claddings, because such materials are not supplied to us from abroad, and, accordingly, we are now dealing with this issue as well. Within the framework of the federal project of the national project "New Nuclear and Energy Technologies," we are resolving all these issues. If we talk about the timing of stable production of such fuel rods from our material with the required composition, provided by our technologies, from 2030 we will confidently have material that provides the necessary properties both in terms of strength and tightness, and, most importantly, in terms of volume.

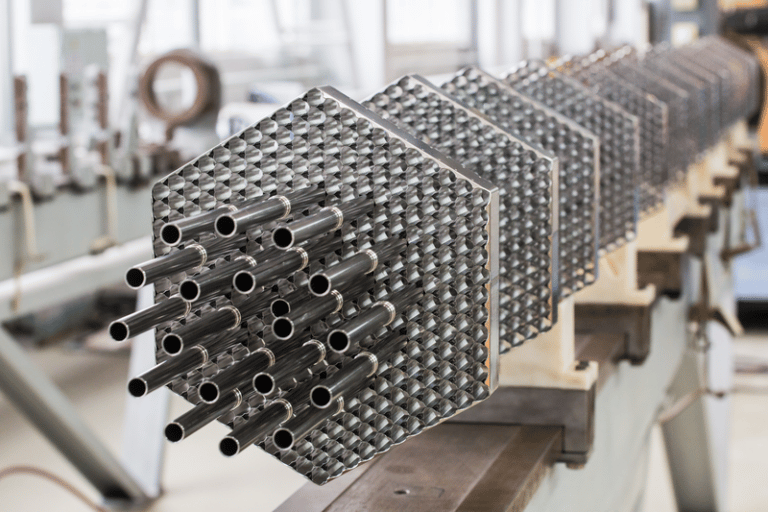

The developed silicon carbide fuel rod claddings are designed to solve two critical nuclear reactor safety problems. Firstly, they will eliminate the possibility of reaching temperatures of 1000 degrees Celsius and above. Secondly, they will prevent steam-zirconium reactions - exothermic processes in which zirconium interacts with water vapor, releasing hydrogen and heat. These reactions pose a serious threat in accidents, as overheating leads to contact of zirconium parts with water, which accelerates the development of the accident. It is expected that the transition to silicon carbide fuel rods will eliminate the need for some safety systems, which will make the construction of nuclear power plants more economical. In addition, they will improve the efficiency of reactors by increasing fuel burnup and the duration of its use.

Read materials on the topic:

Tomsk scientists from TPU turn manure and coal dust into profit

"Baikal" takes off: developer talks about testing the new LMS-901 aircraft

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation