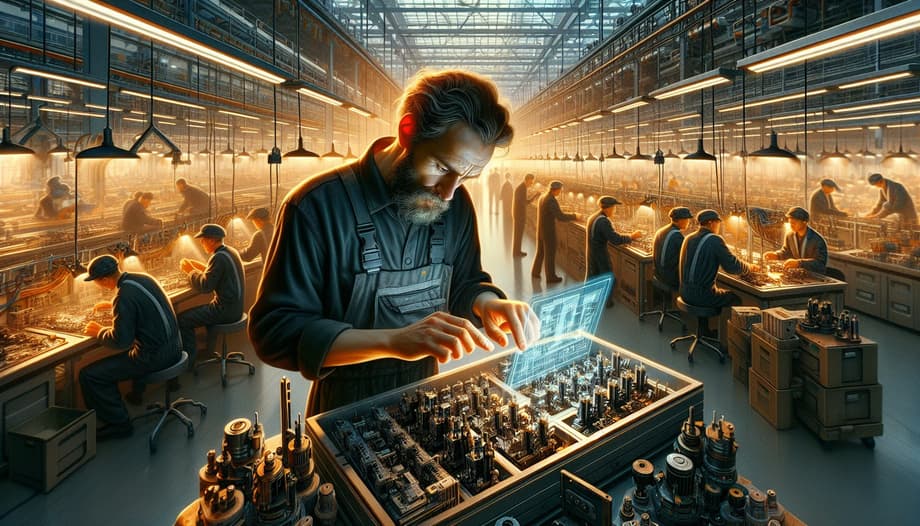

Scientists from St. Petersburg State Marine Technical University have created a special program to improve the quality of parts production. Thanks to the software solution, visualization elements and additional instructions appear at the workplace of a locksmith or assembler.

The program monitors the sequence of assembly operations and displays the recognized parts of the structure on the screen.

According to him, if an employee has performed the operation according to the instructions, the program "allows" him to proceed to the next stage of assembly.

The developers want the software solution to be able to learn in real time. A special module will be created for this. A specialist will be able to video the correct sequence of actions, specify the necessary description in the program, and attach the necessary documents.

The system will also be supplemented with a control system with laser pointers. In the future, they will be used to indicate the desired areas on the assembled parts.

Read more on the topic:

Software Debugging Complex Created in Moscow

Domestic Software for Rocket Engineering Sensors to be Developed in Moscow