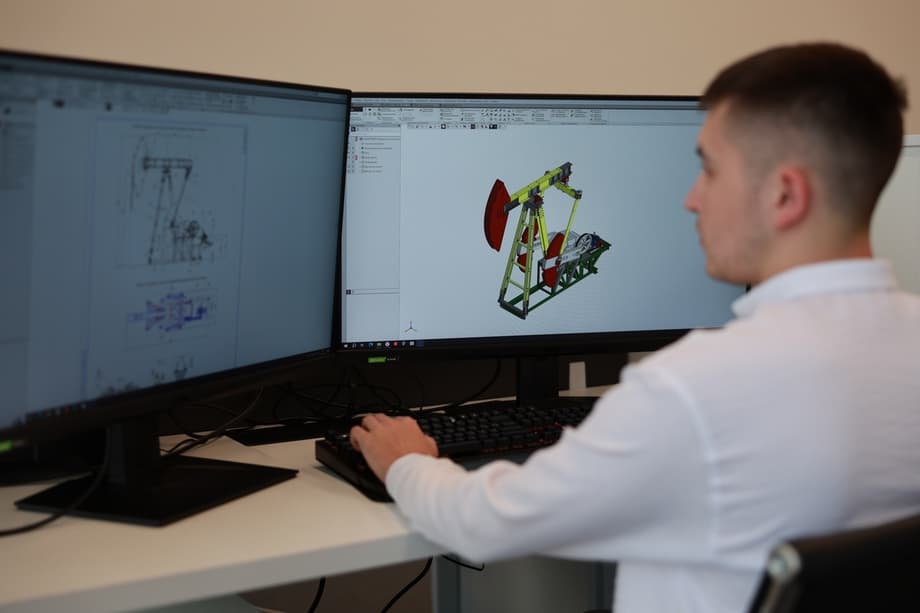

In addition to Tatneft specialists, the Higher School of Oil is participating in the project work. It has involved its design bureau, students, and researchers in the project. Together, they have already created an experimental model of a composite pumping unit.

Composite materials will be used in the parts of the sucker rod pumping unit's walking beam drive. They are lightweight, durable, and corrosion-resistant. In addition, composites reduce the carbon footprint by more than six times compared to metal counterparts.

Constructive solutions were adopted using mathematical models that took into account the mechanical and other characteristics of the material. The result of the joint work was a package of design documentation for an experimental sample.

Now scientists and technologists are working on creating a composite sample of a chain drive.

Tatneft has had its own composite cluster for more than ten years. It produces compounds based on fiberglass and other products: fiberglass profiles for construction purposes, linear and sucker rod fiberglass pipes, fences, railings, and even city benches, trash cans, stadium seats, and manhole covers.

Read more on the topic:

Russia Launches New Universal Chemical Tanker VOLGOTRANS-2502

Russia Showed New Deep-Sea Vehicle KIT-3000 at Army-2024 Forum. It Can Lay Submarine Gas Pipelines

Russia Replaced Parts from the USA, France and Germany for Satellites with Domestic Ones