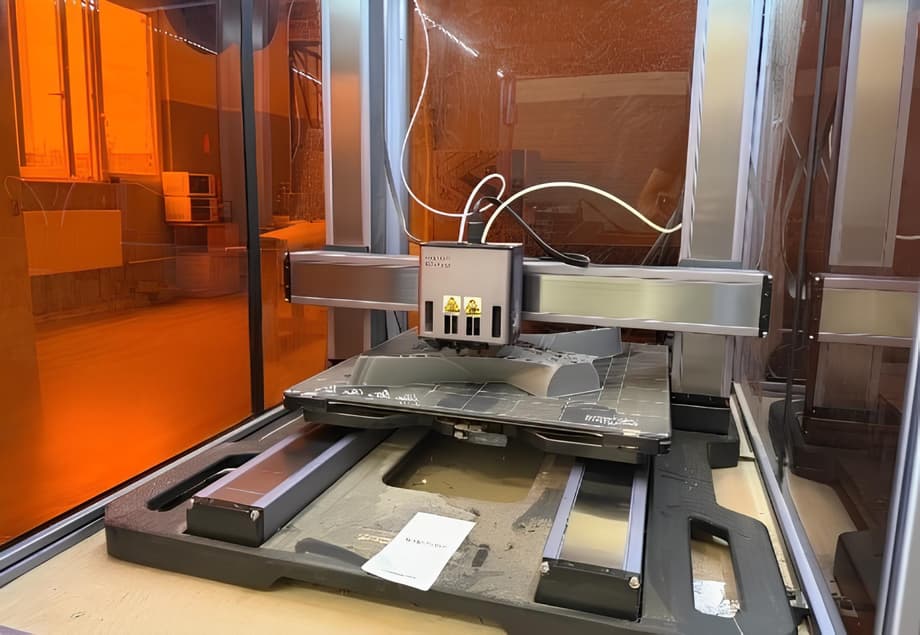

Specialists at SKB-3 (part of the military-industrial holding company "Kingisepp Machine-Building Plant", KMZ) have mastered the technology of 3D printing of model tooling components using thermoplastic polyurethane. These parts are used in the assembly of waterjet propulsion units, according to the KMZ press service.

The structure of polyurethane consists of a block copolymer with alternating hard and soft segments. The material is characterized by strength and elasticity.

Thanks to its properties, thermoplastic polyurethane allows the production of sand cores of complex configuration.

With the new technology, it is possible to increase the serial production of castings and reduce their cost.

At KMZ, the first batch of cores for the reverse gate of the waterjet propulsion unit has already been manufactured, which fully comply with the established production characteristics.

Waterjet propulsion unit creates thrust for the movement of water transport. They work like pumps: sucking water through the inlet and pushing it out through the nozzle. KMZ produces propulsion units for small vessels. Among the developments of the holding are models KMZJET-180, KMZJET-240 and KMZJET-340.