Ulyanovsk Automobile Plant has modernized its production by launching a new metal laser cutting section. This will increase the production of UAZ Pickup and UAZ Profi models with a double cab by 30% and improve product quality.

Oxygen cutting technology and the use of high-tech equipment with smart software guarantee high quality of parts and will significantly improve the consumer properties of UAZs

The technological line is focused on the manufacture of complex spatial 3D elements. Among the manufactured parts are side panels, external and internal side panels, as well as roof elements. The laser cutting section operates in pilot production mode and will soon be put into normal operation.

Earlier www1.ru reported that Ulyanovsk Automobile Plant will continue production of «Hunter»

Read materials on the topic:

Now on home

In medicine and unmanned vehicles, an AI error can cost a person's life, scientists have found

Employees of the state corporation machined and assembled spare parts on their own

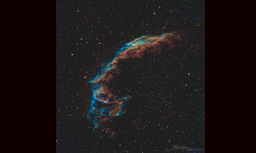

The supernova remnant resembles a cosmic "torn curtain" in the constellation Cygnus

The agreement will expand the participation of Chinese companies in Russian gas projects

New scheme will simplify settlements with employees

The funds will be directed to civilian projects of the Russian state corporation in mainland China

The vehicles include Lada Niva Travel, Largus, Niva Legend, and special pickups based on them

Average trip time will increase by 30%

Digital Document Format Will Become Equal to Paper Format

Among the new UAVs of various types: airplane-type, vertical take-off, quad- and multicopters

J7 is certified only with front-wheel drive and a 1.6 engine

The articulated "accordion" and tri-axle bus are designed for 115-180 passengers