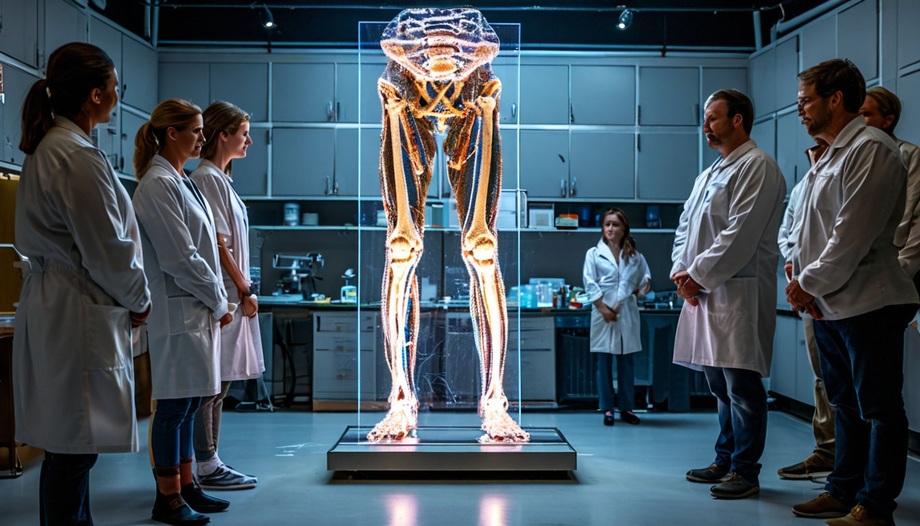

An innovative 3D printing system for creating custom knee prostheses has been developed at MIREA - Russian Technological University. Thanks to this technology, the production of medical devices will be accelerated from several weeks to several days.

The system's operating principle is based on creating a digital model of the joint according to the patient's individual parameters. This uses data from computed tomography (CT) and magnetic resonance imaging (MRI). At the next stage, a prototype is printed on a 3D printer from a special plastic.

The production process includes several stages. First, a digital model is created, then a prototype is printed to test functionality. After approval by the surgeon, the final product is made of titanium. This approach solves the main problem of standard prostheses - their incomplete correspondence to the patient's anatomy.

The technology combines medical imaging, computer modeling, and 3D printing into a single process. This not only speeds up the preparation of the prosthesis but also makes personalized prosthetics accessible to ordinary medical centers.

The main feature of the technology is the combination of medical imaging, computer modeling, and 3D printing into a single process. This solves the key problem of standard prostheses - their incomplete correspondence to the patient's anatomy.

The project has successfully entered the "Accelerator RTU MIREA" program, which indicates the serious potential of the development for practical application in the medical field.

Read more materials on the topic:

PNNPU students created limb prostheses that can be printed on a 3D printer

Holds everything from a needle to a hammer: Russia has developed a new "Zakhvat" hand prosthesis