The "Reshetnev" company has created a closed-loop production cycle for waveguides, which are important radio engineering devices for the passage of radio signals on board spacecraft.

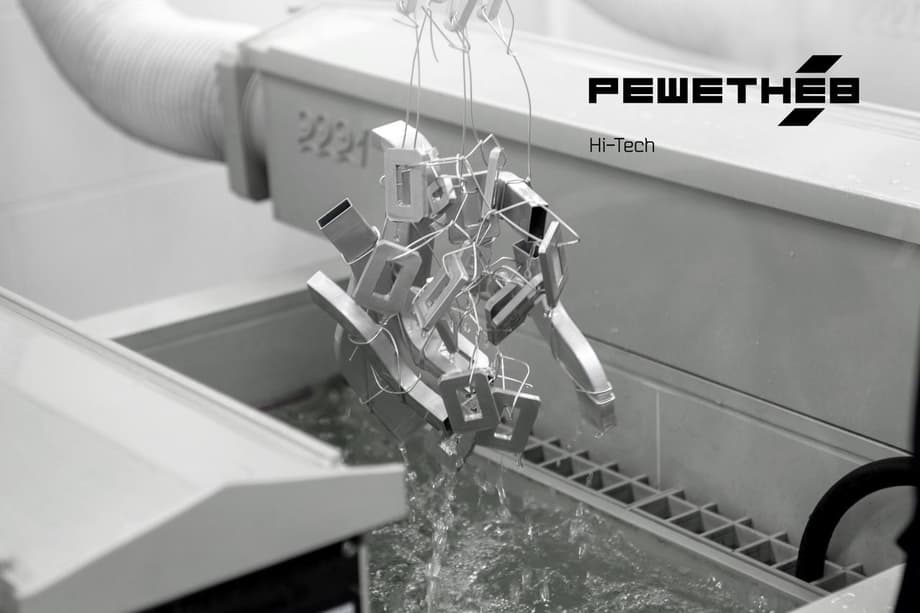

The workshop, which is engaged in the mechanical processing of parts and the manufacture of waveguides, occupies an area of 1,296 square meters and includes workplaces for various operations, such as mechanical, electroplating and heat treatment, welding, soldering, locksmith and assembly work, as well as product quality control.

The main advantage of the new approach is the application of lean manufacturing principles, which made it possible to eliminate the need to transport waveguides between different workshops and sections, as well as to abandon related procedures, such as conservation and incoming inspection. This significantly reduced the manufacturing cycle of waveguides, while ensuring their high quality and radio engineering characteristics.

As a result of these changes, JSC "Reshetnev" now fully satisfies its own needs for waveguides, manufacturing products with various section radii and using modern high-performance technologies to implement design solutions.