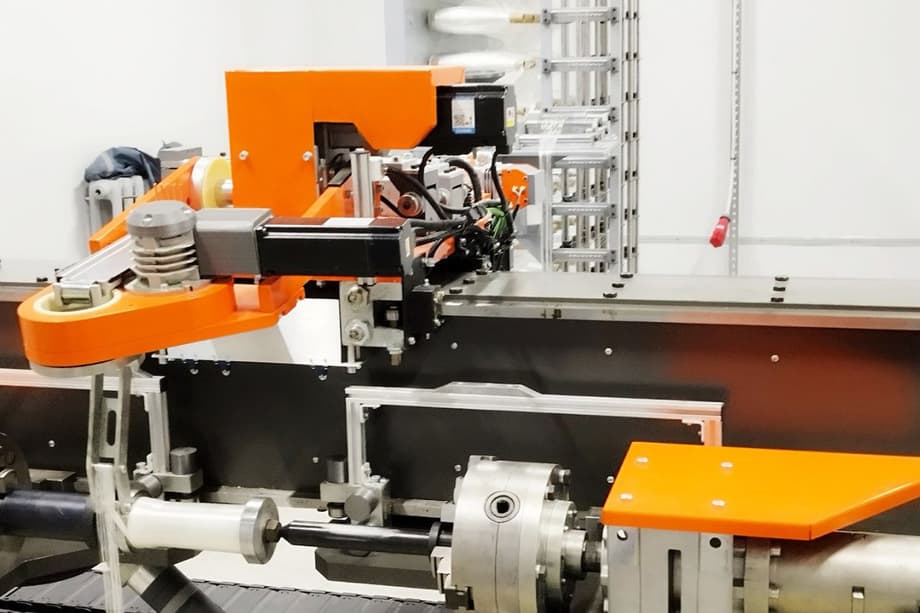

Scientists from Novocherkassk have developed a unique robotic machine that creates composite parts using the winding method. It was delivered to the Kirov plant "Mayak" (part of the "Kalashnikov" concern).

How does the winding technology work?

Each fiberglass thread passes through a bath with liquid resin, is impregnated with it, and then wound onto a rotating mandrel. Then the wound fibers are compacted, and the formed part hardens.

The machine can weave more than 2.5 kilometers of composite fabric per hour.

Features of composite parts created by winding:

- Not susceptible to corrosion and do not rot

- Withstand temperatures up to +300 °C

- Service life - more than 50 years

- Low thermal conductivity

- Light weight

As emphasized in the concern, the complex surpasses foreign analogues in its technical characteristics.