At the Moscow Aviation Institute (MAI), a unique method has been developed for the strength analysis of aircraft parts and other complex technical structures. Engineers have created a technology that combines the classical photoelasticity method, which records changes in the optical properties of a transparent material when loaded, and 3D printing, allowing for faster research.

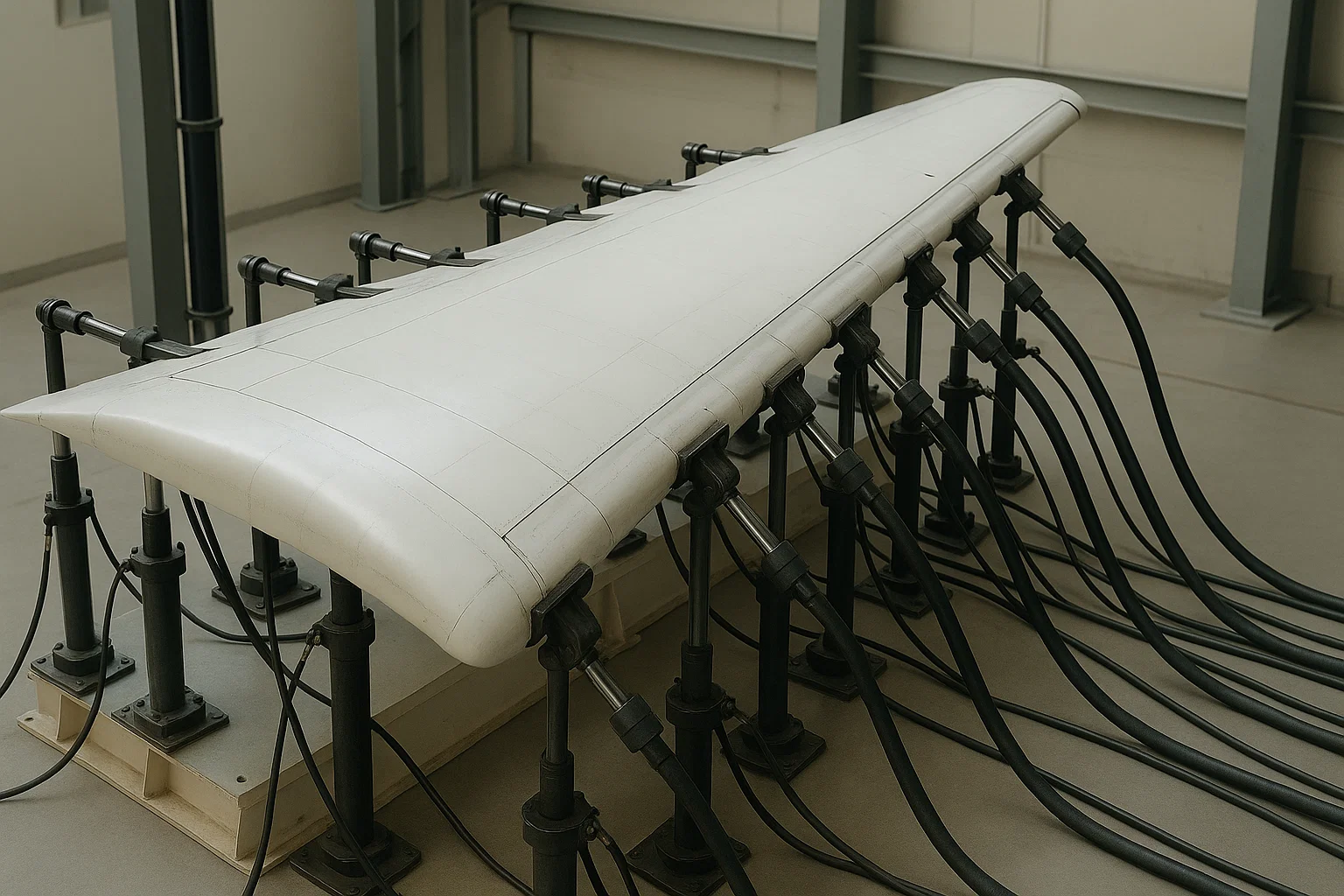

The method, created at departments 203 "Design and Engineering of Engines" and 904 "Engineering Graphics", is designed to calculate permissible loads on aircraft components, such as wings, fuselage, and engine parts, as well as for application in mechanical engineering, shipbuilding, and energy. It uses transparent polymer models made on a 3D printer, which show colored stripes under polarized light, displaying the distribution of internal stresses. This allows identifying vulnerable areas of parts and adjusting their design.

If you shine polarized light through the parts, characteristic colored stripes appear in them, reflecting the picture of internal stresses. A thermal imager works on a similar principle, only we record not temperature, but mechanical loads.

Previously, resin casting was used to create models, which took weeks, and in case of errors, it was necessary to start all over again. The new technology reduces the preparation time of models to several hours, simplifying the testing of complex parts. According to MAI engineer and postgraduate student Roman Sabitov, the method also helps to check the correctness of new Russian programs for strength analysis, which is especially important in conditions of limited access to Western solutions.

Our approach allows for independent experimental verification of the correctness of computational models, thereby providing additional testing of new Russian developments and accelerating their implementation in industry.

The research will be completed in 2026, after which the method will be patented and implemented in industry.

Read more materials on the topic:

Course to Venus: MAI is creating technologies for missions to a distant planet

No expiration date: MAI has created an engine for spacecraft with almost unlimited service life

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation