Scientists from Perm National Research Polytechnic University (PNRPU) have developed a technology for small-tonnage production of methanol directly at oil and gas fields. The project, aimed at solving the problem of reagent shortage and high cost, received a patent and a grant under the "Priority 2030" program.

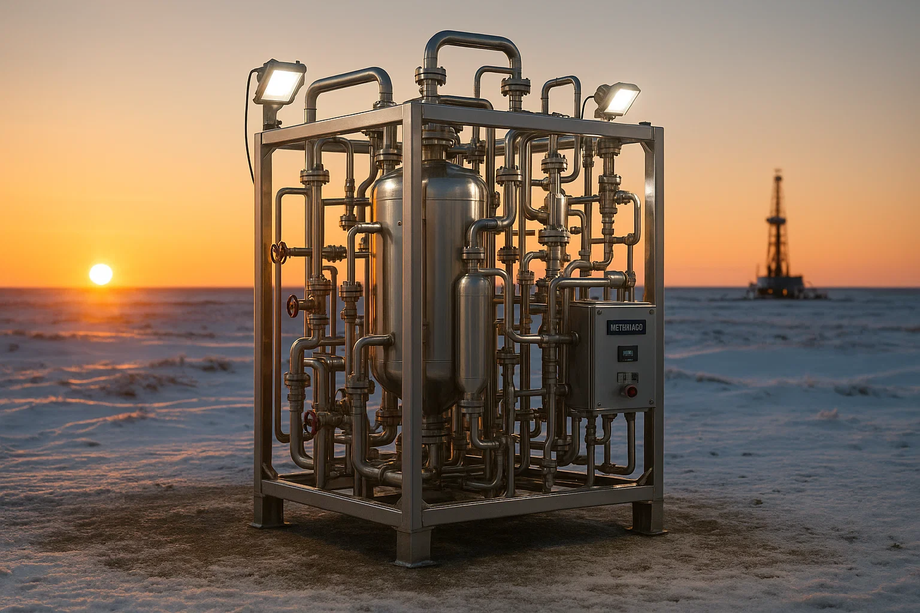

The new development is a block-modular complex based on universal chemical reactors. Its key advantage is its compactness and the absence of the need for complex infrastructure, such as steam generators and air separation units, which makes it cost-effective for use in remote and small fields.

The complex's productivity can reach 40 thousand tons of methanol per year. According to developers' estimates, the cost of on-site production is 3-4 times lower than the purchase and delivery of reagent from large plants due to high logistics costs and storage costs.

As the project participants explained, the technology allows the use of associated petroleum gas and low-pressure natural gas as raw materials. This helps enterprises not only save on reagents, but also meet environmental requirements for associated gas utilization.

Currently, the project has reached a technology readiness level of 4 (laboratory test confirmation). The next step will be the creation of a pilot industrial sample with a capacity of up to 1 thousand tons of methanol per year, followed by scaling.

Read more on the topic:

Mathematical model from NUST "MISIS" will increase the efficiency of the mining industry

A new mineral powder production workshop has opened in the Amur Region

Five new hydraulic structures will be built in the Astrakhan Region by 2030