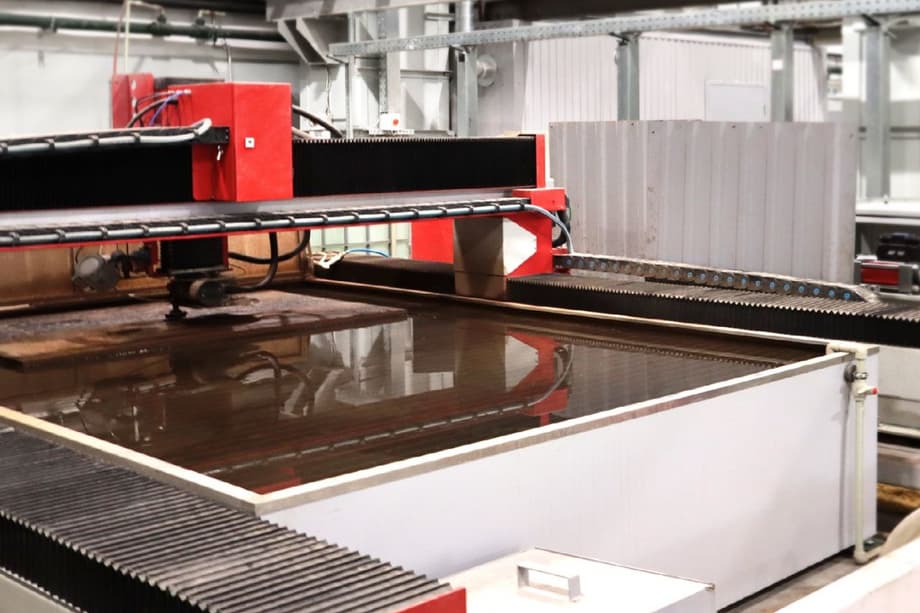

Kirovsky Zavod Mayak PJSC (part of the Kalashnikov concern) has launched a new hydroabrasive unit (HABR). This was reported by the company's press service.

This equipment has become an addition to the existing hydroabrasive unit and will increase production volumes.

All mechanisms of the hydroabrasive unit are controlled from the CNC rack. The cutting field of the machine has been increased, the software allows you to set up for a whole sheet of metal, so the output is a cleaner, larger part that requires less processing in the future.

The new unit doubles the output of blanks for parts due to operation in two shifts. It is capable of processing aluminum up to 25 mm thick, as well as cutting cast iron, natural stone and titanium up to 150 mm thick. Cutting is carried out using a water-abrasive mixture supplied under high pressure at a speed of up to 900 meters per second. Cutting accuracy - up to 0.1 mm.

For the cutting process, special sand with the addition of abrasive particles and water are used for the operation of the unit, which is cleaned of impurities by the machine system. This avoids negative impact on the material.

Earlierwww1.ru reported that UNTK abrasive cleaning, cutting, and turning machines werereleased in Russia.

Read materials on the topic:

UVZ delivered new wagons for transporting hot pig iron

With an efficiency of 89%: UVZ has developed a new electric motor

With an increased body and load capacity: RM Rail has certified an innovative gondola car