Scientists from Siberian Federal University have created a prototype of high-strength material based on zirconium dioxide. According to the developers, this material can replace imported raw materials in the production of implants, mining equipment parts, and microelectronics components.

Zirconium dioxide is a ceramic material with incredible wear resistance and strength. It is widely used in various fields, including dentistry, microelectronics, and mining equipment. It is produced from the natural mineral baddeleyite, which has a greenish or yellowish tint.

Baddeleyite deposits are located in South Africa, Brazil, and Russia, which makes it possible to partially or completely replace imported zirconium dioxide with domestic material, emphasized scientists from the Institute of Engineering Physics and Radio Electronics of the Siberian Federal University.

This is an import substitution project. Today, a limited number of companies in the world produce high-purity zirconium dioxide. It is mainly used for the manufacture of dental implants. We are interested in creating our own material that can become a raw material for domestic medical devices, including for dentistry and orthopedic surgery.

As the researcher emphasized, it is not enough to simply obtain highly purified zirconium dioxide powder. It is also necessary to ensure the stability of its phase composition and properties.

The fact is that the most durable phases of this material are formed at temperatures above 1200 °C. However, when cooled, they quickly lose their properties. To preserve the result of heat treatment, it is necessary to fix the material, for example, using yttrium oxide.

Today, SFU scientists are developing a technology for converting baddeleyite raw materials into a water-soluble form. They are also studying its chemical composition, structure, and particle size. In addition, specialists are experimenting with cleaning methods.

Depending on the degree of purification, our material can be used to form parts for ball mills that grind ore in mining and metallurgical production and in the geochemical industry, or to solve various microelectronics problems.

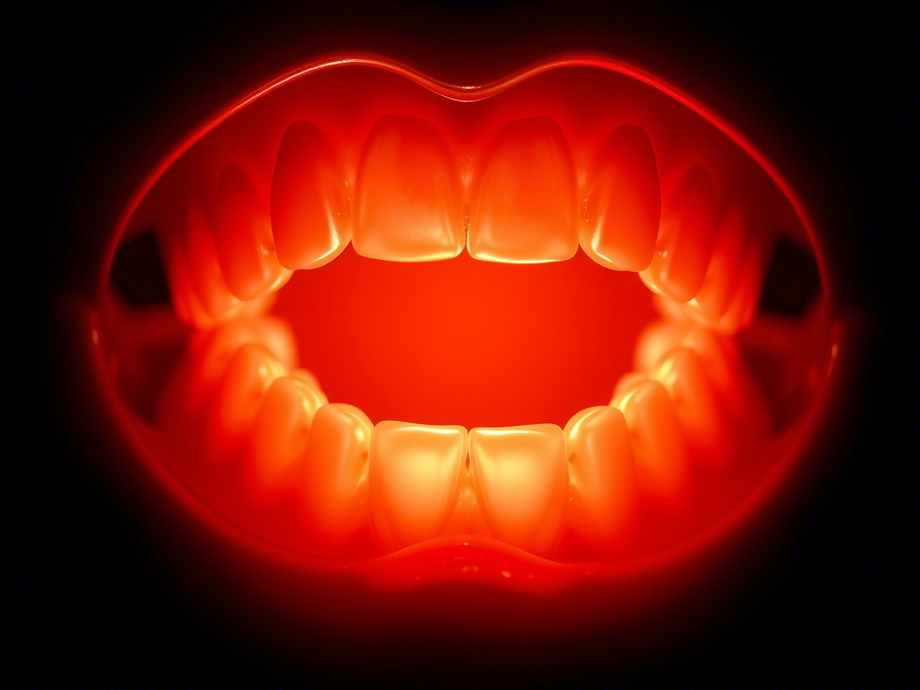

Zirconium dioxide in dentistry is valued for its strength, which increases under the influence of chewing load. This material can be used to make single crowns, bridge prostheses, implant elements, and aesthetic veneers.

Zirconium oxide can also be used in the production of components for artificial hip joints. This direction is promising, and there are practically no imported medical devices on the Russian market. Scientists from the Siberian Federal University plan to develop a technology for manufacturing prototypes of such components in their laboratory.

In the future, specialists intend to organize an experimental production facility on the basis of the university, where the method of manufacturing materials based on zirconium dioxide will be tested.

Earlier, Peter the Great St. Petersburg Polytechnic University developed a new material for medical implants. Its base is tantalum, a strong and biocompatible metal. Unlike aluminum, it is not toxic.

Read materials on the topic:

A Russian soluble patch implant has been developed for the treatment of oncological diseases

Rostec has created a unique implant for the treatment of pelvic fractures

Rosatom scientists have developed implants with a biocompatible coating