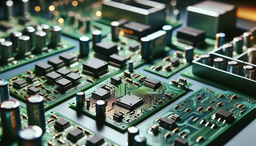

Specialists from Tomsk Polytechnic University have developed an innovative technology to protect metal chemical reactors from destruction.

The solution is based on fluoroplastic coatings, fluorine-containing polymers, which are applied by spraying. The first samples have already been transferred to an industrial partner from Novosibirsk.

Fluoroplastic coatings demonstrate resistance to mineral and organic acids, alkalis, solvents and oils at temperatures up to 120°C. This makes them an effective replacement for traditional enamel layers, which wear out faster in aggressive environments. For example, the material can withstand contact with hydrofluoric acid (HF), which is critical for petrochemistry and pharmaceuticals.

The key know-how is the mobility of the technology. Coating application units can be deployed directly at the sites of enterprises, processing reactors with a volume of up to 6 cubic meters. This reduces the cost of transporting and installing equipment.

The development was the result of interdisciplinary collaboration. In the future, the technology will be adapted for other industries, including the food and perfume industries. Scientists are also working on expanding the temperature range of application of coatings.

Corrosion of reactors threatens depressurization, emissions of toxic substances and contamination of products with metal particles. The new coating not only extends the service life of equipment, but also increases the safety of production. This is especially important for "clean" processes, such as the synthesis of pharmaceutical substances - iron impurities can make a batch defective.

Now on home

Foreign delegation visited the "Parus electro" electrical equipment manufacturing plant

"The new system is more powerful than the existing version"

Sergey Marzhetsky stated that placing orders in the DPRK could become a realistic solution under sanctions

NDTV: India Aims to Acquire 40 Combat Aircraft

The autonomous platform can travel up to 60 km

Casting technology allows creating elements with geometry that cannot be obtained by other methods

The manufacturer promises compliance with global safety and quality standards

Remterminal to establish rolling stock production by 2032

Inside - Sleeping Places for Four, Shower, Toilet, and Hot Water

The device is equipped with BAM-OS 18×55 gas cylinders with red hot pepper

Almost 70% of cars in the country have exceeded the 10-year mark

The complex will start operating as early as 2026