The Design and Technological Institute of Scientific Instrument Engineering of the Siberian Branch of the Russian Academy of Sciences has developed an innovative automated complex for monitoring the cladding of fuel elements (fuel rods). This was reported in the press service of the university.

The development has successfully passed the tests.

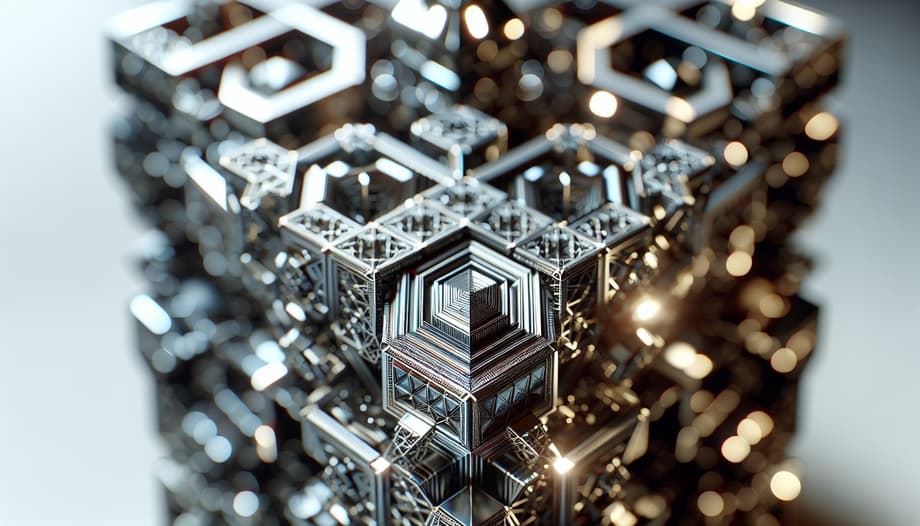

The complex combines four optoelectronic systems for monitoring geometric parameters and detecting defects on the surface of zirconium fuel rod cladding. The complex is installed directly in the production line and carries out monitoring in the flow.

If defects are detected, the cladding is redirected to an additional conveyor with a special microscope. It is capable of performing high-precision measurements of defect depth with a resolution of up to 1 μm.

Artificial intelligence is used to detect defects. Scientists have created an extensive database of images of acceptable and unacceptable defects of various types. This allows the neural network to effectively learn and improve the accuracy of diagnostics.

The novelty was tested at the Chepetsky Mechanical Plant in Udmurtia.

As a result of the tests, the complex was recognized as ready for implementation at JSC "ChMZ".

Earlier www1.ru reported that Rosatom has started to complete the testing of the fuel of the future.

Read materials on the topic:

Russian scientists have found a new additive for biodiesel