Russian specialists from the D.V. Efremov Institute of Electrophysical Apparatus (NIIEFA) have successfully completed a multi-year cycle of manufacturing and testing a full-scale prototype of a highly loaded panel of the first wall of the vacuum chamber of the International Thermonuclear Experimental Reactor ITER. The final stage was the measurement of the geometric parameters of the prototype after the tests.

Now, scientists from the "Rosatom" enterprise need to obtain permission to start mass production of the panels. According to the agreement with the International ITER Organization, 179 of them have to be developed and manufactured. The work is responsible and high-tech: the Russian panels will receive one of the maximum loads compared to other ITER components.

What is ITER

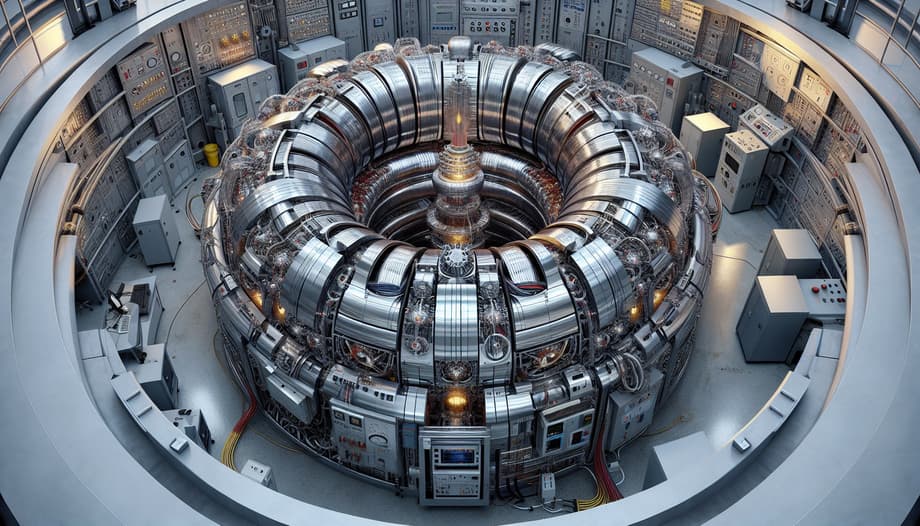

ITER is an international experimental thermonuclear reactor being built in France, in the Bouches-du-Rhône department, based on a tokamak. Russia, the United States, India, China, South Korea, Japan, and the countries of the European Union are jointly working on the project.

Tokamak is an experimental facility designed to use thermonuclear fusion energy. High-temperature plasma is required for thermonuclear fusion and energy production.

This heat will be used to produce steam, and then, with the help of turbines and generators, converted into electricity without generating CO2. ITER's controlled thermonuclear fusion will help the world move to a cleaner and safer type of energy production.

On the Russian side, the State Corporation "Rosatom" fulfills its obligations in the ITER project, and the work is coordinated by the "Rosatom" private institution "ITER Project Center". The first wall panels of the reactor, developed at NIIEFA, are one of the most important and technically complex components of ITER: along with the divertor, they are in direct contact with hot plasma.

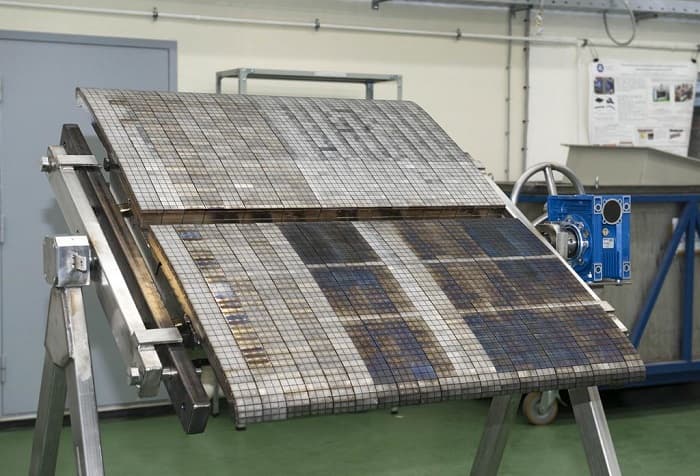

Each panel consists of 40 so-called fingers. Each finger is a complex multi-layer structure of beryllium cubes 16 × 16 mm, soldered onto CuCrZr bronze, which is connected to a steel base by diffusion welding. Approximate overall dimensions of one panel are 2 × 1.5 × 0.5 m, weight is about 800 kg. The panels have different shapes - scientists of JSC "NIIEFA" have developed about 40 variants of their design.

How is the ITER project useful for Russia?

In addition to the global benefit for science, Russian scientists, with their participation in it, have received a number of developments and achievements. These are:

- unique experience and competencies in the field of designing plasma-facing components;

- technologies for manufacturing, control methods and tests have been created and mastered for this area;

- production and experimental test benches;

- established cooperation with a number of "Rosatom" enterprises, key participants in the production process.

Thus, the country has a base for the start of future national projects in the field of development and creation of plasma-facing components for controlled thermonuclear fusion facilities.

Now on home

The 136 hp engine successfully started at -30 ℃

Experts visualized heavy vehicles of the future

The main feature of the exhibit is its ability to move under its own power

Specialists from SUSU and NPO "NTES" took into account logistics needs: the weight of the cargo is displayed in real time

The new method provides a temperature regime for drones in the aircraft's cargo compartment

The main purpose of the development is to store and supply working fluids to the pipelines

Combat vehicles transformed into APCs with serious drone protection

"ODK-Klimov" Reduces Financial Claims Against Kazan Helicopter Plant

Russian scientists have recorded a fresh flare zone in the south of the Sun

Army's "Boomerang-10" Implements Target Acquisition Function

The price of the aircraft without engines starts from 233 million rubles

The operation takes only 12 seconds per wheel