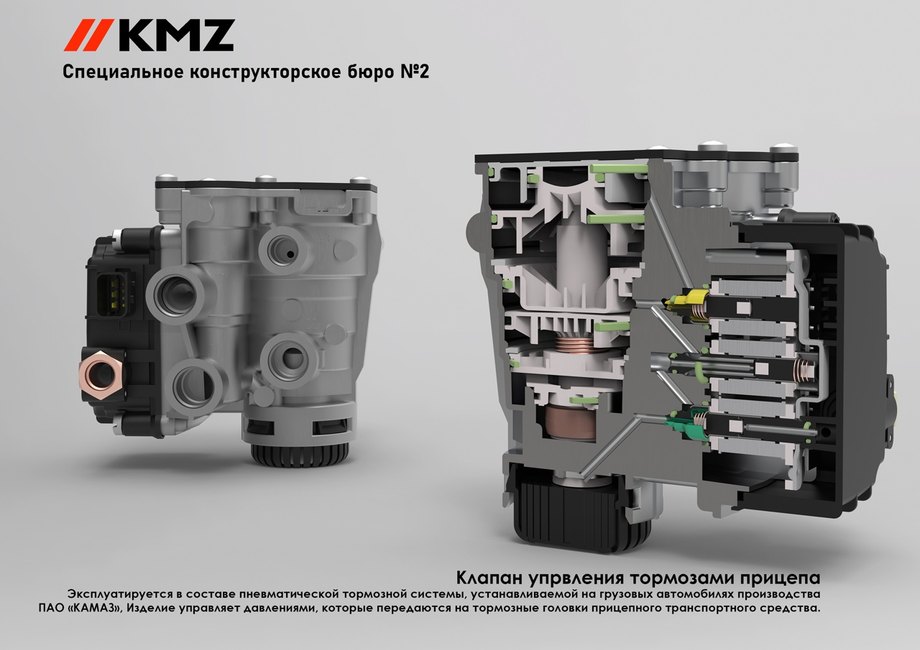

Specialists of the SKB-2 design bureau (part of the Kingisepp Machine-Building Plant holding) have completed work on the reverse engineering of the trailer brake control valve for KAMAZ trucks. This was reported by the company's press service.

The valve is a key component of the pneumatic brake system. Its function is to control the pressures that are applied to the brake mechanisms of the towed vehicle.

The developed product includes a relay valve, inlet and outlet valves, as well as a backup and shut-off valve. The design is also equipped with a built-in pressure sensor, the contacts of which are protected from short circuits. The operation of the entire device is controlled by an external unit via electrical signals.

Reverse engineering allows you to create a complete analog of the component, ensuring its compliance with the original technical characteristics and safety requirements. This development is aimed at import substitution and maintaining the operability of the commercial vehicle fleet.

Read more materials on the topic:

Diesel engine speed controller repaired at KMZ: they travel to any point in Russia

New diamond processing equipment put into operation at the ALROSA factory

Vladmorrybport plans to increase container transshipment capacity to 700 thousand TEU by 2027