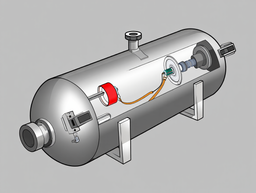

The United Engine Corporation (UEC) has begun mass-producing "grown" parts for environmentally friendly combustion chambers for industrial engines. Specialists from the Samara-based "UEC-Kuznetsov" use a comprehensive additive manufacturing technology.

Engineers are printing parts for a low-emission combustion chamber (LCC) of an NK-36ST industrial engine. The "grown" components have already been tested and put into series production.

The production of parts uses methods of direct and selective laser growing, which reduced the complexity and increased the material utilization rate.

The use of LCC in engines reduces emissions of harmful substances into the environment.

Earlier, www1.ru reported that the service life of Russian engines was proposed to be increased using a laser.

Read also on the topic:

Setting records: Tutaev Motor Plant produced the 25,000th automotive reduction winch

Two ambulifts based on the KAMAZ Compass-9 chassis were delivered to Sheremetyevo Airport

KAMAZ-4280-F5 Vega bus and low-floor trolleybus KAMAZ-62825 were shown at an exhibition in Smolensk