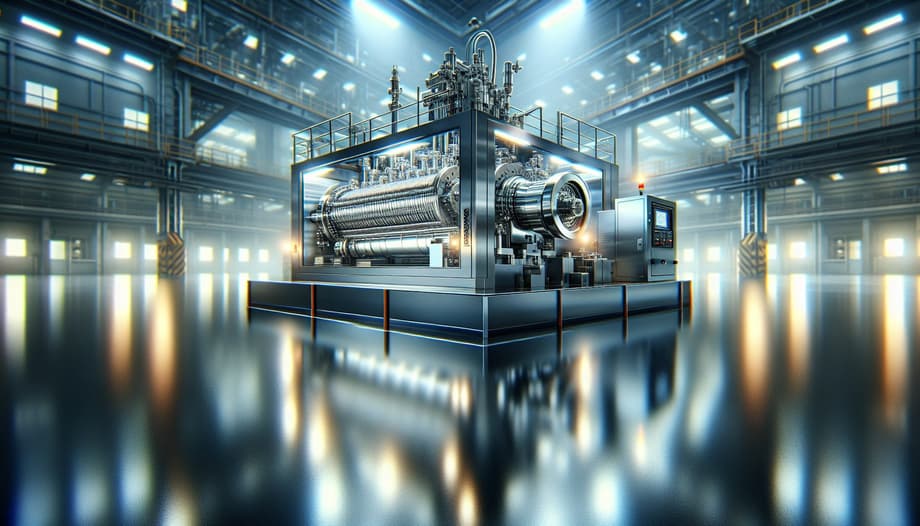

Scientists from the Ufa University of Science and Technology (UUST) have developed Russia's first machine for dry electropolishing of parts, marking a significant step in the field of metallurgy and engineering. This advanced technology allows achieving a mirror finish on the surface of products without changing their geometric dimensions, which is an important advantage for many industrial processes.

The method is based on the ionic removal of material from the surface layer under the influence of electrical processes, which ensures high efficiency and processing quality. The use of anion exchangers and the application of electrical potential makes the process particularly interesting for use in high-tech industries such as engine building and nuclear energy.

In addition, this method is environmentally friendly and requires low energy consumption, making it attractive for a wide range of applications. In the face of the growing need for import substitution, the creation of domestic equipment and consumables for electropolishing is becoming particularly relevant. Professor Nikolai Krioni, head of the laboratory, emphasizes the importance of developing new installations for processing complex-shaped and large-sized parts, which directly affects the operational characteristics of aircraft gas turbine engines.

Scientists have also developed requirements for the design of a prototype electropolishing robot machine, which will differ from foreign counterparts in wider technological capabilities. The machine has already attracted the attention of companies such as PJSC "ODK-UMPO" and JSC "ODK-Aviadvigatel", which indicates a high interest in this technology in the market.

Read more on the topic:

LMZ Successfully Implemented a Modern Plasma Cutting Unit

"Kalashnikov" Replaced Italian High-Precision Spindles for Russia Through Import Substitution